Overview: PROTATO KIT

In current agricultural production, plant disease and pest management adheres to the principle of “prevention first, integrated control.” With economic development and rising consumer demand, agricultural products with low pesticide residues or produced under pesticide-free regimes are increasingly favored by the market. If preemptive diagnostic approaches with superior cost-effectiveness compared with periodic chemical control become available, they could reduce pesticide use and environmental burden while improving economic returns. “Earlier detection, Better economic benefit.” One of our interviewed farmer said. Accordingly, the development of high-performance, cost-effective diagnostic devices for crop diseases holds substantial application potential.

In synthetic biology, the practical deployment of engineered genetic circuits likewise depends on compatible hardware platforms that can translate theoretical designs into reproducible, scalable, and field-deployable applications. The lack of detection and control systems aligned with the requirements of biological reactions often constitutes a key bottleneck in transitioning from laboratory validation to real-world implementation.

To address the dual needs of agricultural practice and biotransformation, we developed the modular, integrated disease forecasting and diagnostics platform PROTATO KIT.

Two version of PROTATO KIT were developed: The portable, field-deployable PROTATO KIT Air enables rapid, on-site testing by individual farmers. For centralized cultivation and large-scale monitoring, we introduced PROTATO KIT Pro, which integrates smartphone connectivity, camera-based image acquisition and transmission, algorithm-driven intelligent monitoring, and precise reaction temperature control to enhance the efficiency, robustness, and scalability of disease management. In parallel, to facilitate translation from laboratory concepts to application, the KIT adopts a modular architecture: by replacing only the electrode corresponding to the target, the system can be readily adapted to detect multiple diseases.

Circuit Design: PROTATO KIT Circuitry

The circuit design of the PROTATO KIT aims to enable efficient transduction and accurate detection of biological signals associated with Pseudomonas syringae pv. tomato—specifically trehalose and glucose—into electronic readouts. Building on electron transfer processes that occur in bioreactions such as enzyme-catalyzed transformations, we designed an electro-bio system to monitor enzyme-catalyzed reactions. Specifically, we constructed a biosystem targeting Pseudomonas syringae pv. tomato that adopts a logic-gate paradigm: upon recognizing disease-associated biological cues (analogous to a high-level input in electronic circuits), the system expresses trehalase, which converts trehalose in the reagent into glucose. The role of our hardware is to establish a detection framework for the resulting glucose signal and, through different microcontrollers and corresponding assemblies of components, realize application-specific detection functions tailored to diverse scenarios and requirements. The output detection system comprises the following three modules:

- Enzyme Biosensor Electrode

- Signal Amplification Circuit

- Signal Processing System

Enzyme Biosensor Electrode

We selected glucose oxidase (GOD)-modified screen-printed electrodes (SPEs) as the core sensor component. In aqueous solution under aerobic conditions, glucose is oxidized by glucose oxidase (GOD) to generate hydrogen peroxide and gluconic acid. The hydrogen peroxide subsequently undergoes redox reactions at the electrode. As the electrochemical processes proceed, the continuous transfer of electrons and migration of anions and cations give rise to the measurable current signal.

The carbon-based working and counter electrodes, along with a silver reference electrode, ensure high conductivity and signal stability, while the porous 3D electrode surface allows for efficient enzyme immobilization, improving sensitivity and reproducibility.

The fabrication steps for the screen-printed enzyme electrode are as following picture:

Fig.1 Fabrication steps sketch map

And for more specific instructions, we have hardware biosensor electrode protocol here.

Signal Amplification Circuit

To precisely detect the electrical signals arising from charge transfer during the glucose enzyme–catalyzed reaction, we designed an amplification circuit based on a three-electrode electrochemical system. A three-electrode system, comprising a working electrode (enzyme-modified screen-printed electrode), a counter electrode, and a reference electrode, is employed to enable precise control of voltage and current during reactions within the PROTATO KIT Assembly container system. This configuration effectively minimizes interference from non-Faradaic processes in electrochemical reactions, thereby ensuring measurement stability and reproducibility.

Our circuit design is illustrated in the figure below.

Fig.2 Hardware circuit

Signal Processing System

Considering different agricultural applications, we developed two hardware configurations

Background investigation

Based on our HP practice, farmers use a dual approach to monitor crops in practical agricultural production. They combines scheduled large scale inspections at key growth stages with immediate on the spot testing. These two strategies directly inspired our two design solutions.

PROTATO KIT Air

PROTATO KIT Air uses an STC8G microcontroller, enabling portable, real-time detection and display of disease results. It features low cost, low power consumption, and easy operation, allowing frontline farmers to perform on-site leaf sampling and immediate testing—"detect and act immediately."

Fig.3 PROTATO KIT Air assembly process

Table1 Portable Kit BOM Table (1 CNY = 0.1405 USD, 2025/10/6)

| Components | Number | Price(CNY/num) | Sum(CNY) | Sum(USD) |

| R4600 SLA(For 3D Print Assembly) | 43g | 0.1/1g | 4.3 | 0.60 |

| MCU STC8G1K08A | 1 | 0..83 / 1 | 0.83 | 0.12 |

| Operational Amplifier (Dual-channel) | 1 | 3.2 / 1 | 3.2 | 0.45 |

| LED | 1 | 107.1 / 1000 | 0.11 | 0.02 |

| Female Header | 3 | 162.4 / 500 | 0.97 | 0.14 |

| Ceramic Capacitor | 2 | 33.85 / 500 | 0.14 | 0.02 |

| Resistor | 8 | 104 / 5000 | 0.17 | 0.02 |

| JFET | 1 | 137.79 / 150 | 0.92 | 0.13 |

| Veroboard | 1 | 38.13 / 50 | 0.76 | 0.11 |

| Total | 11.4 | 1.60 |

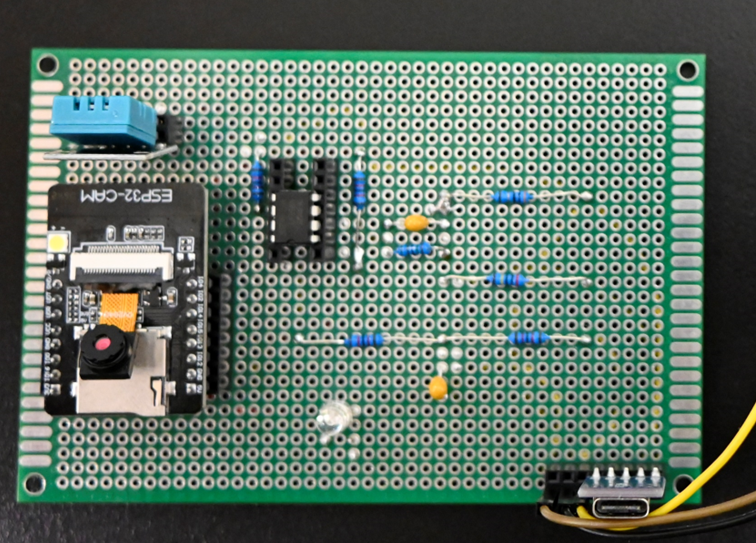

PROTATO KIT PRO

PROTATO KIT Pro is designed for greenhouses and large farms. Built on an ESP32 platform, it integrates Wi-Fi, camera modules, and a customized mobile application. Users can remotely access multiple devices, obtain glucose-based detection data, and combine them with real-time images. With AI-assisted image analysis, suspicious plants can be automatically identified for further inspection.

Fig.4 Multi-PROTATO KIT

Fig.5 PROTATO KIT Workflow

Fig.6 PROTATO KIT Pro Coreboard

Model Validation

Concurrently, an analytical model was established and rigorously analyzed to investigate the operational feasibility and quantitatively evaluate the detection sensitivity of the fabricated enzyme electrode for glucose.

Mechanical Design: PROTATO KIT Assembly

PROTATO KIT Air Assembly provides a complete workflow from sample pretreatment to biochemical detection and then to visual signal output. It contains three core modules:

- Grinding System - A hand grinder with a detachable porous plate allows mechanical cell disruption to release plant sap efficiently.

- Container System - An anti-threaded structure prevents accidental loosening during handling, ensuring operational safety.

- Reaction Room - Standardized electrode ports ensure stable insertion for signal acquisition, while detachable design facilitates post-experiment cleaning. After use, inactivating reagents can be added via a one-way valve to safely handle biochemical waste.

Fig.7 PROTATO KIT Assembly

Safety

To ensure biosafety and environmental protection:

- One-way valves for all reagent ports to prevent leakage.

- Reverse-thread lock between container system and reaction room prevents accidental opening during operation.

- Modular disassembly allows for safe, contact-free cleaning.

- Inactivating agents (e.g., guanidine hydrochloride) can be added post-detection to neutralize biological materials.

Further Improvements

Society Inspiration

Based on in-depth discussions with technical staff and Mr. Liu, a tomato grower (iHP, June 15, 2025) , we have implemented a critical optimization to the hardware detection scheme: departing from the original spGFP luminescence design in favor of adopting trehalase as the biomarker. This decision was primarily driven by the following two considerations: First, from a detection performance perspective, enzymatic reactions demonstrate faster kinetics than luminescence-based reactions, and their products are more amenable to precise quantification. Second, from a practical application standpoint, this detection method effectively avoids interference from ambient light in outdoor environments, significantly enhancing the hardware system's robustness and reliability in real-world field conditions.

Meanwhile, feedback from frontline farmers has provided valuable insights for the future iterations of our KIT.

“A great tool for early tomato disease detection. It helps me reduce pesticide use and save costs. However, the bottom chamber is a bit narrow—sometimes the liquid might spill during operation.”

“The grinder lid tends to loosen during transport.”

“The electrode insertion requires several steps. Can this be simplified?”

Based on this feedback, we plan the following upgrades:

- Replace the reagent port with a unidirectional valve to enhance sealing;

- Add waterproof gaskets to the grinder;

- Integrate the electrode directly within the reaction chamber to simplify operation.

- After the Grand Jamboree, we updated the hardware design based on user feedbacks

Fig.8 Updated PROTATO KIT

Future Development: PROTATO KIT Pro Max

We are developing the third enhancing version: PROTATO KIT Pro Max, a fully automated multi-modal detection platform featuring:

- Built-in environmental monitoring (temperature & humidity sensors),

- Wireless data transfer to mobile devices,

- Potential integration with robotic systems for automated sampling and inspection.

Although the full system is still under development, several core components—such as the ESP32-based control board, modular detection chamber, and Wi-Fi data module—have been completed and tested successfully.

Reproducibility and Accessibility

All 3D housing designs are modeled in SOLIDWORKS and available for download here. Electronic circuit designs and component lists are open-sourced to allow reproduction with common low-cost materials. This ensures any iGEM team or researcher can easily replicate and modify the hardware for detecting other plant pathogens or biochemical analytes.

All design files (3D models, circuit schematics, and firmware) are uploaded on our GitHub / wiki repository for community use.

Summary

PROTATO KIT bridges synthetic biology and practical agriculture by turning biochemical reactions into accessible, field-deployable detection signals.

It demonstrates:

- Clear utility for synthetic biology and agricultural applications

- Practical user testing and iteration

- Verified signal conversion and detection functionality

- Comprehensive documentation for reproducibility by future teams

We envision PROTATO as a universal platform for on-site biosensing, empowering farmers and expanding the real-world reach of synthetic biology.