The project, initiated by the NSFLS-CHINA team, aims to revolutionize the production of natural astaxanthin through synthetic biology techniques. We used directed evolution techniques to rationally design the key enzyme (β -carotene hydroxylase) to obtain high-performance engineered strains and relied on a mature E.coli fermentation platform to efficiently produce high-purity, high-bioactive natural configuration (3S,3'S) astaxanthin through engineered E.coli, and we have filed a Chinese invention patent application (application number: CN202511043781.7) and a PCT international patent application (application number: PCT/CN2025/124139) to protect our technology worldwide. Compared with traditional extraction and chemical synthesis methods, our technology has competitive advantages of low cost (reduced by 50-70%), high purity (>95%), strong sustainability and good product consistency, achieving efficient, green and low-cost production of astaxanthin. Our products are mainly targeted at the cosmetic raw materials market (B2B) and the terminal anti-aging and sensitive skin care products market (B2C). In terms of business model, we adopt a "B2B first, then B2C" approach, initially entering the market as a supplier of high-end raw materials, serving the cosmetics and health care products industry; The long-term goal is to build our own brand and launch our own brand of skincare products (B2C) for end consumers when the funds and channels are mature. The project has significant technical feasibility, economic feasibility and huge market potential, aiming to become the world's leading provider of green astaxanthin solutions.

Our company aims to become a global leader in providing green cosmetic raw materials and solutions based on synthetic biology technology.

Our primary product is to supply astaxanthin raw materials, selling high-purity astaxanthin raw materials to cosmetic and health supplement manufacturers; our secondary product is the skin care and makeup products made from our produced astaxanthin raw materials, such as astaxanthin masks and anti-aging makeup eyeshadows.

We hope to provide efficient, safe and affordable natural astaxanthin products to the global market through sustainable innovative technologies, improving consumers' skin health and promoting the green development of the beauty industry.

Our target customers are anti-aging seekers 、sensitive skin and people with damaged barriers and cosmetics and health product manufacturing enterprises.

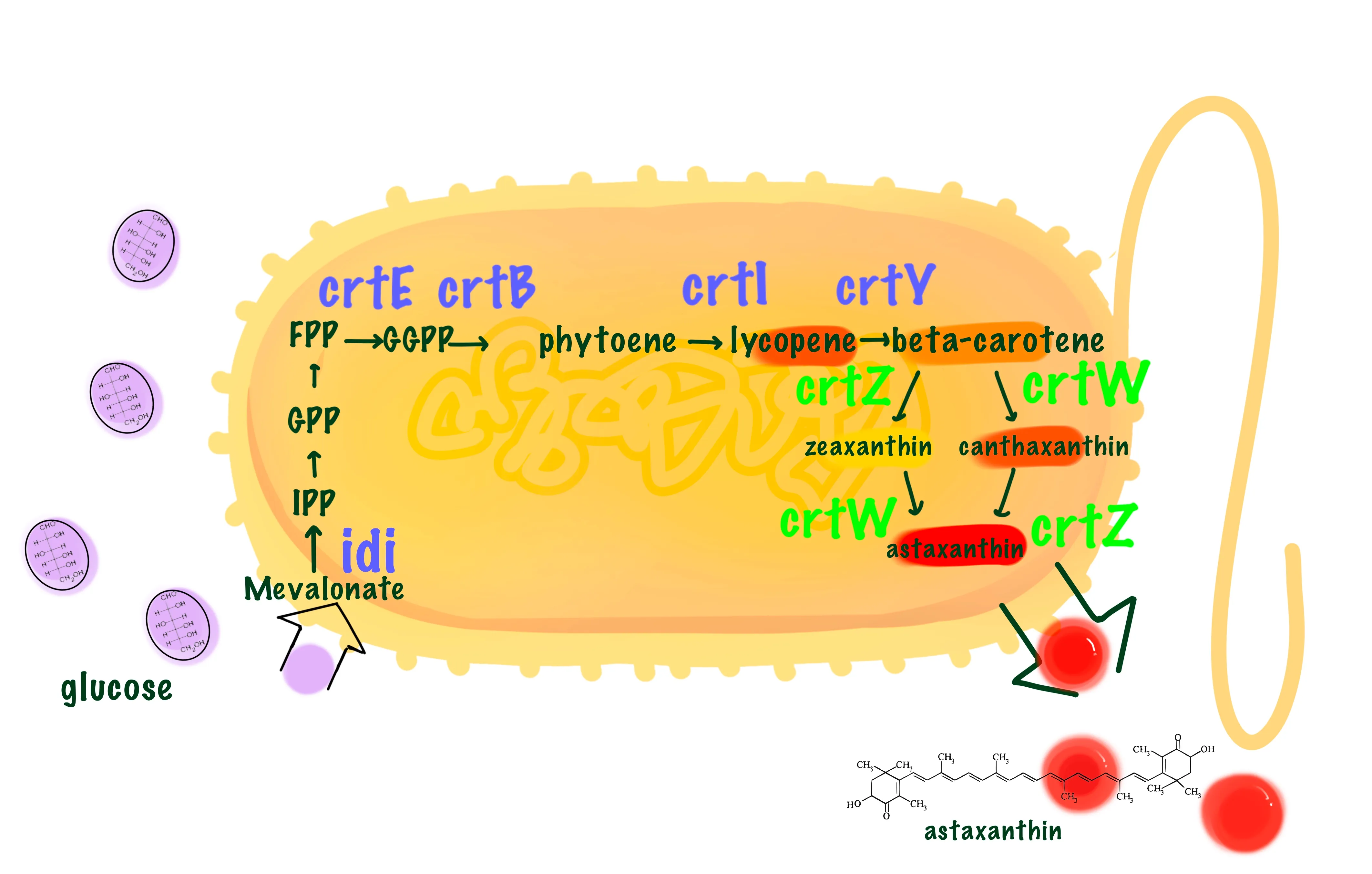

Figure 1. The core technical approach of our research.

Figure 1. The core technical approach of our research.

E. Coli Top10 Strains:

E.coli BL21 (DE3):

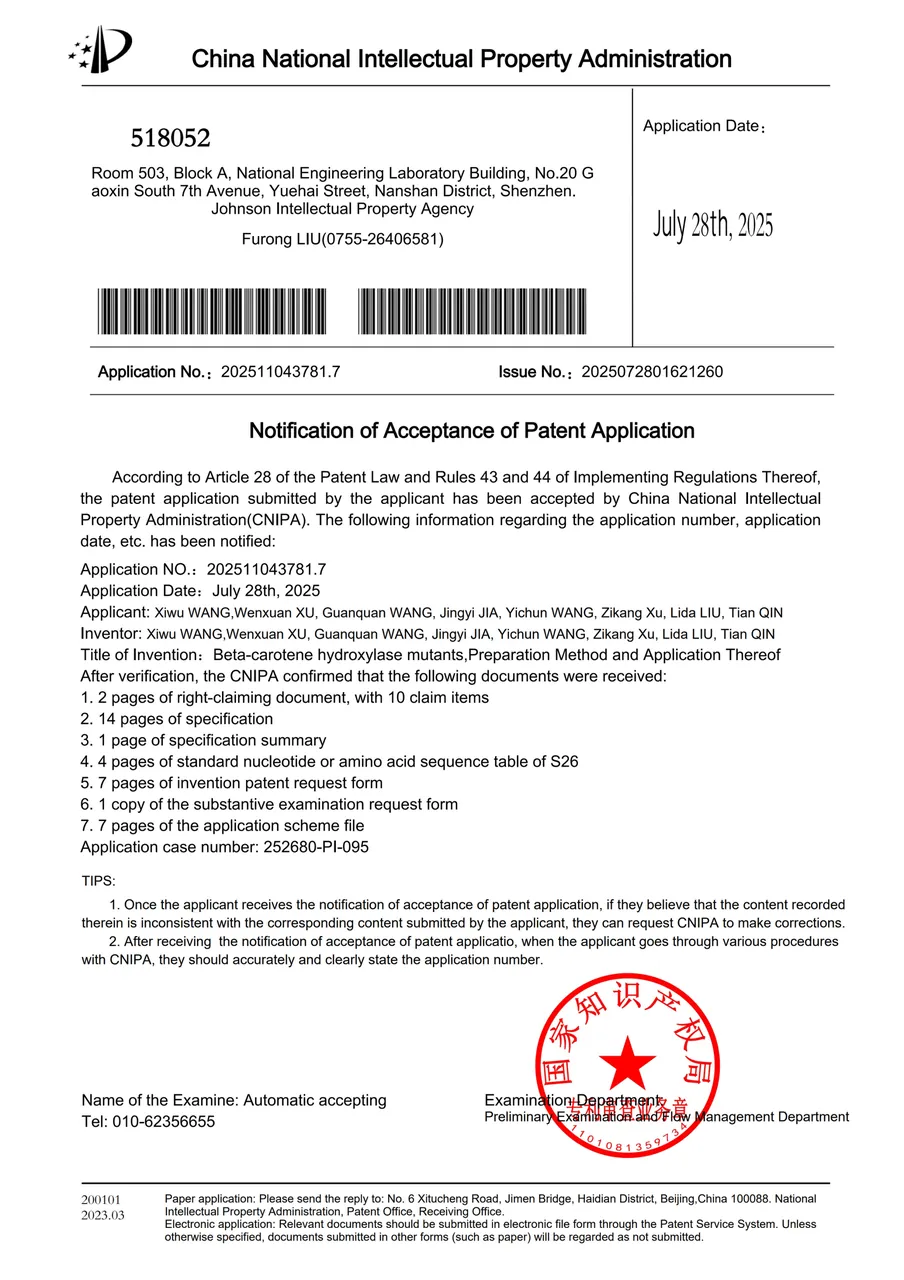

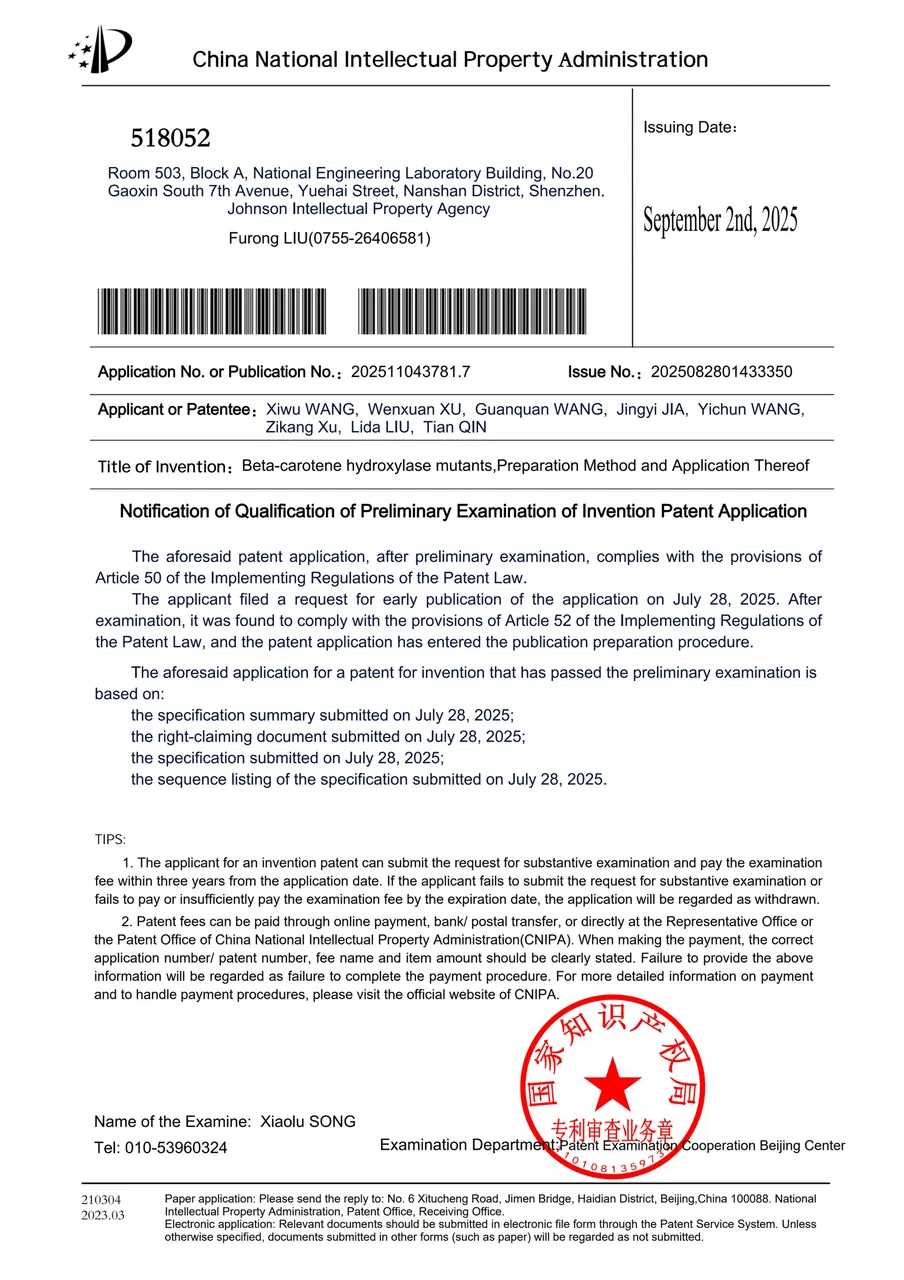

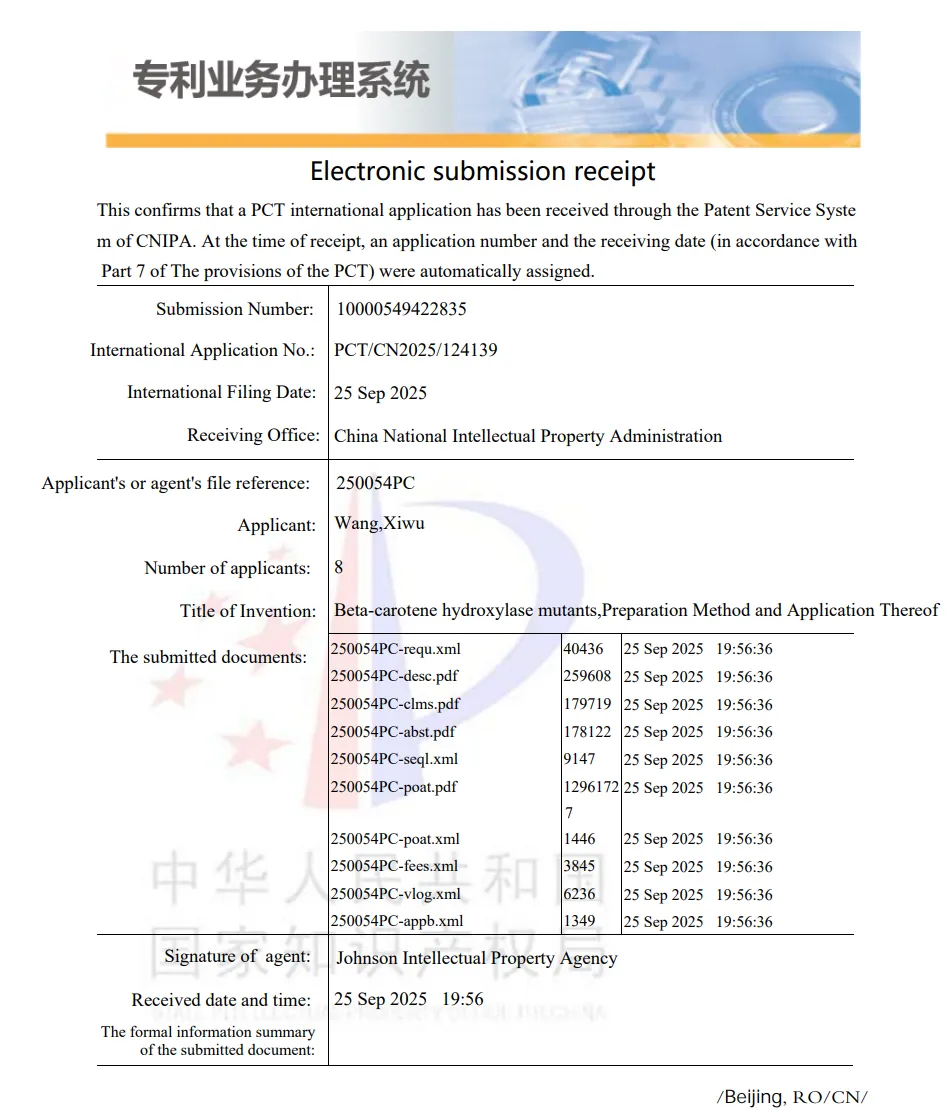

China is the major exporter of astaxanthin worldwide, with numerous customers and competitors in the domestic and oversea market. To ensure our technological and product global competitive advantage, our team protects our technologies worldwide through Chinese invention patent applications and PCT international patent applications. Additionally, We take the application of Hong Kong trademarks as the first step to safeguard our brand's promotion in overseas markets (subsequently, we will carry out targeted trademark protection based on the specific regions and countries where our brand is promoted).

The attached files below are our patent and trademark application materials.

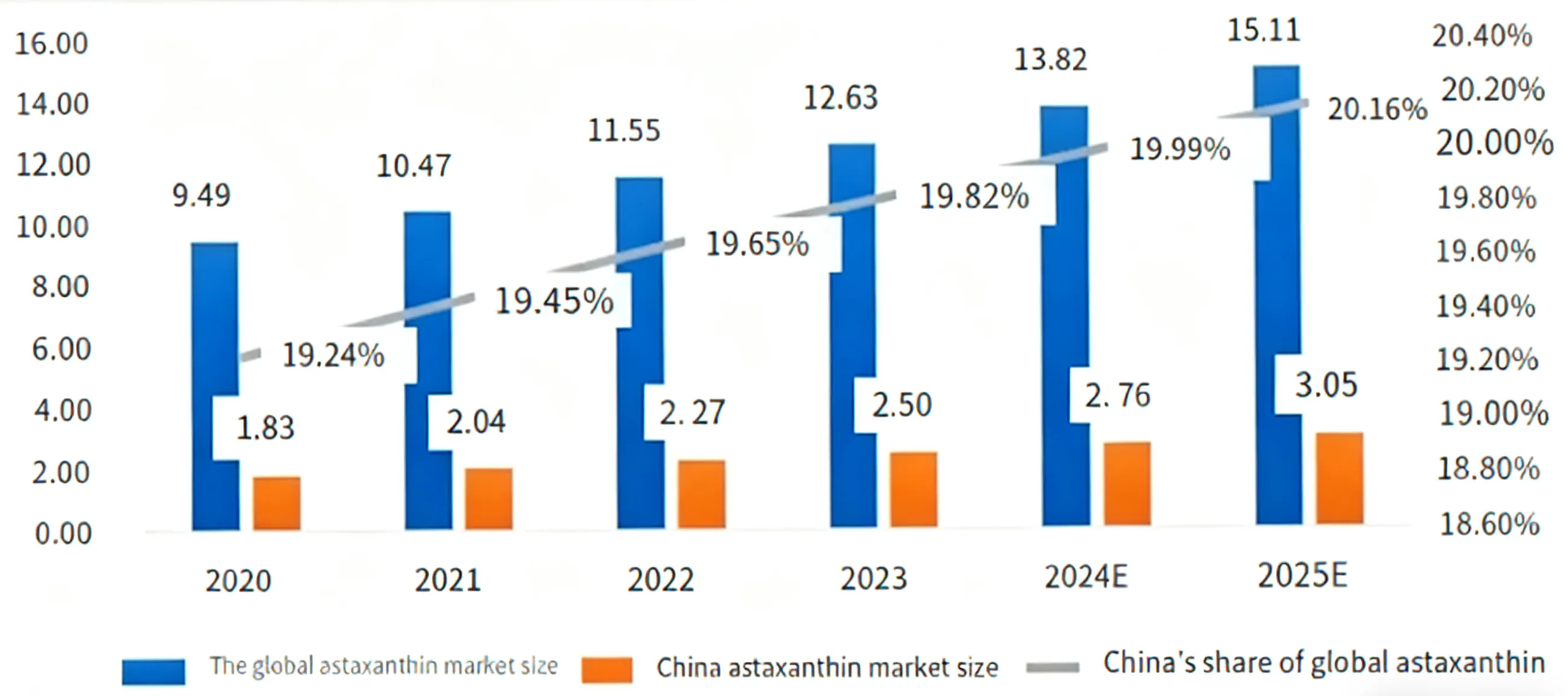

According to Shangpu Consulting, the global astaxanthin market size grew steadily from 949 million yuan in 2020 to 1.263 billion yuan in 2023, and the compound annual growth rate (CAGR) of the global astaxanthin market is expected to reach 9.37% by 2029. Additionally, according to Business New Knowledge, the global cosmetic-grade astaxanthin market size is expected to reach approximately $2.416 billion in 2024 and $5.113 billion in 2031, with a compound annual growth rate of 11.5% from 2025 to 2031.

China, as the world's second-largest consumer of astaxanthin, holds A significant position in the global supply chain, with a market share of approximately 40 percent, and consumption is growing at an annual rate of 18 percent (data source: Yunnan Green A Bio, "China Astaxanthin Industry Market Development Analysis and Investment Prospect and Investment Strategy Report 2025 to 2030").

In addition, the simplification of the "Cosmetic New Ingredient Filing Regulations" will keep the annual growth rate of new ingredient filings containing astaxanthin above 50%, which will drive the further expansion of astaxanthin's application and market size in the cosmetics sector.

Figure 2. Global and Chinese Astaxanthin market size from 2020 to 2025 (Unit: 100 million yuan)

Figure 2. Global and Chinese Astaxanthin market size from 2020 to 2025 (Unit: 100 million yuan)

China has become the world's largest exporter of astaxanthin, with exports reaching $347 million in 2024, mainly to the United States, Japan and the European Union, with the U.S. market accounting for 41.2%. With the increasing awareness and demand for astaxanthin in the international market, there is huge export potential for astaxanthin cosmetics from China.

NSFLS-China has gained a certain understanding of the needs of potential customers through interaction with stakeholders.During the interview with BiSheng Biotechnology Company, we learned about the activities required for the commercialization of the product. Considering the needs of the actors that we had previously understood, we decided to utilize the properties of astaxanthin red and antioxidant to create a non-toxic and harmless cosmetic. During the interview, Dingjian Testing helped us access the materials that need to be submitted for the product's launch, the laws and regulations that need to be followed, the preservation issues during transportation of the product, as well as the precautions in terms of promotion, such as packaging and advertising. We distinguish potential customers from other stakeholders, dividing them into target groups with the intention to purchase and use our products, as well as groups and individuals interested in our products. We roughly divide potential customers into the following two categories:

We can provide brands with stable, high-quality, cost-advantaged natural astaxanthin ingredients for developing pre-makeup essences, primer products, pore care products, etc., to enhance product competitiveness.

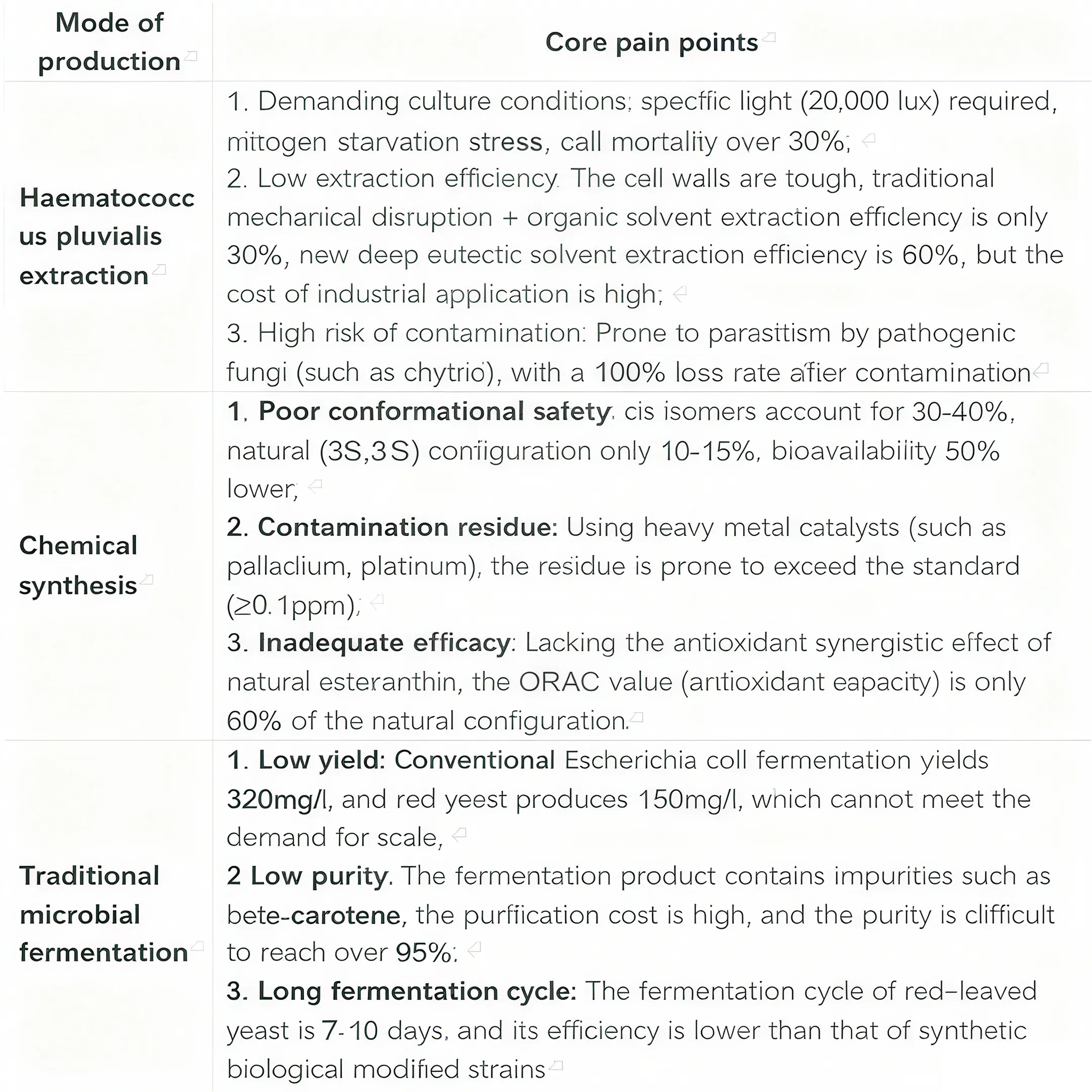

Table 1. Three core pain points and significant market gaps in existing astaxanthin production and application solutions.

Table 1. Three core pain points and significant market gaps in existing astaxanthin production and application solutions.

Poor stability: astaxanthin is prone to oxidation under light and high temperatures, traditional oil-based products have a shelf life of only one year and need to be used up within one month after opening, with a consumer complaint rate of 18% (Tmall after-sales data);

Poor water solubility: Astaxanthin is insoluble in water and can only be used in oil-based products (such as essence oil), not compatible with water-based products (such as toner, mask liquid), limited application scenarios, missing out on 35% of the water-based skincare market.

Low bioavailability: The human absorption rate of common oil astaxanthin is only 15% (PubMed study data), and high doses are required to be effective, increasing consumer costs;

Exaggerated efficacy claims: 38% of astaxanthin skin care products have exaggerated claims such as "anti-aging in 7 days" and "reducing wrinkles by 50%" (NMPA 2024 sampling report), and the actual efficacy is not supported by clinical data, leading to a decline in consumer trust.

Safety risks: 12% of astaxanthin skin care products detected heavy metals (such as lead, mercury) or hormones (such as dexamethasone) (NMPA sampling), long-term use can lead to skin dependence, hormone-induced face;

Poor individual fit: The proportion of sensitive skin in Asians (38%) is higher than that in Europeans and Americans (25%), but existing imported products are mostly designed for European and American skin types, with a pH value that is slightly alkaline (7.5-8.0) and does not match the pH value of Asian skin (5.5-6.5), with an irritation rate of 22%.

Currently, the production of astaxanthin (algal extraction, chemical synthesis) faces bottlenecks of low yield and insufficient product activity. Biocatalysis using highly specific carotenoid hydroxylase (which has been proven to be compatible with E. coli β-carotene) is a highly promising alternative method. The Machine Learning combined with directed evolution technology we studied can efficiently engineer this enzyme, improve its catalytic efficiency, enhance its tolerance in the host, and directly target the metabolic bottlenecks of traditional methods such as chemical synthesis and natural extraction. Our key advantage lies in the fact that the engineered E.coli system can significantly reduce production costs by over 50% compared to traditional methods, and can efficiently produce natural active astaxanthin, demonstrating significant technological and industrialization potential.

The production of astaxanthin using engineered E.coli demonstrates remarkable economic potential, with its core advantage being a reduction of approximately 50-70% in comprehensive production costs. This is attributed to multiple efficiency improvements: first, a significant reduction in the fermentation cycle, which lowers the allocation of fixed costs and energy consumption; second, the efficient utilization of the substrate β-carotene, reducing raw material consumption; finally, the simplification of the purification process, saving separation media and labor hours; after querying the study on the production of glycolic acid from low-cost biomass by E.coli fermentation and its separation and purification, we learned from and relied on the mature, stable, and easily scalable fermentation process platform of E.coli, reducing the risk of technology transfer and the threshold for scale-up[3].

In addition, the astaxanthin produced by engineered bacteria has extremely high purity (up to over 95%), and its biological activity and storage stability are superior to those of the natural extraction method. Due to the different sources of naturally extracted astaxanthin, its molecular configuration also varies. E.coli can directionally synthesize astaxanthin with the left-handed (3S, 3'S) configuration through gene editing technology, which is also the most common and highest antioxidant activity configuration in nature. The astaxanthin synthesized by Haematococcus pluvialis has a left-handed (3S-3'S) structure, which is basically the same as the astaxanthin configuration in aquaculture organisms such as salmon, and has extremely strong biological activity. By producing astaxanthin through E.coli, it is possible to precisely synthesize astaxanthin with a specific configuration and high biological activity by means of gene editing and other methods, simulating the synthesis of left-handed astaxanthin by Haematococcus pluvialis, thereby enhancing its biological activity. This not only increases the product value, reduces storage and transportation losses, but also facilitates entry into high-profit markets such as cosmetics, further enhancing its economic attractiveness.

The current challenge lies in the fact that high-density fermentation and product synthesis have strict requirements for environmental control (temperature, induction conditions), which increases the complexity of process control and initial investment, and limits immediate large-scale production. However, its disruptive cost reduction ability, excellent product quality, and mature chassis system have laid a solid foundation for the industrial economic feasibility of its large-scale application, with a clear prospect.

Currently, through social practice and interviews, it can be understood that in today's society, the female population and even some male individuals pay high attention to skin anti-aging issues, and they generally have a need to have young and healthy skin. As people reach middle age, their skin often faces problems such as dryness, lack of moisture, loss of luster, and loss of elasticity, and astaxanthin can precisely provide practical and effective solutions to these problems. Relevant research Cosmetic benefits of astaxanthin on humans subjects - PubMed[4] has confirmed that astaxanthin has the ability to penetrate deep into the skin, not only repairing the damaged skin tissue structure but also strengthening the skin's natural protective barrier, and further playing a role on this basis: helping to reduce the depth of wrinkles, fade skin pigmentation, and ultimately improve the overall health of the skin and restore its plump and firm texture. It is worth noting that the astaxanthin we promote is prepared using enzyme engineering E.coli production technology, which demonstrates excellent economic potential - the comprehensive production cost is reduced by approximately 50-70% compared to traditional methods. On the one hand, it reduces the fixed cost allocation and energy consumption by significantly shortening the fermentation cycle, efficiently utilizes the substrate β-carotene to reduce raw material consumption, and simplifies the purification process to save separation media and man-hours; On the other hand, by leveraging the mature, stable, and easily scalable fermentation process platform of E.coli, it reduces the risks of technology transfer and the threshold for scale-up. Meanwhile, it can directionally synthesize left-handed (3S, 3'S) configuration astaxanthin (purity can reach over 95%), which is the most common and has the highest antioxidant activity in nature, consistent with the active configuration of astaxanthin in Haematococcus pluvialis and aquaculture organisms such as salmon. Its biological activity and storage stability are both superior to those of natural extraction methods, better ensuring anti-aging effects and reducing product storage and transportation losses. From the perspective of demand, women of all age groups in the community have a certain demand for anti-aging. The NSFLS-CHINA team plans to conduct promotional activities in nearby communities and distribute trial packs of anti-aging masks containing the above-mentioned highly active astaxanthin. If the product receives favorable feedback during small-scale community trials, it can not only achieve word-of-mouth promotion within the community, but also leverage its cost advantages on the production side and high activity advantages on the product side to facilitate further promotion of the product within the community, laying the foundation for its subsequent entry into high-profit markets such as cosmetics.

Compared with other astaxanthin products using natural extraction or chemical synthesis, the research results of NSFLS-CHINA have certain advantages in terms of yield and cost. Our astaxanthin is currently suitable for various applications, including personal use and small-scale production, and will continue to be applicable in the future. In the future, we will consider how to apply astaxanthin to facial masks and contact manufacturers to expand production. With these advantages, we can quickly expand our market coverage.

We use E. coli to build cell factories. Our communication with stakeholders indicates that our solutions to urgent needs are safer, more environmentally friendly, and more cost-effective. The NSFLS-CHINA team obtains better protein structures through computer modeling and prediction to enhance activity, and proposes product usage methods not available on the market, such as colored lip masks, skin-care oil paints for Chinese drama facial makeup, and addresses the issues faced by people with oily skin in Europe and America, where anti-aging products like astaxanthin essence oil that nourish the skin with oil are too greasy, difficult to absorb, and may even lead to clogged pores, acne, etc.

Our goal is to use synthetic biology gene-edited E.coli to replace traditional Haematococcus pluvialis for astaxanthin production, convert the extracted astaxanthin into high-quality and affordable facial masks, and promote them.

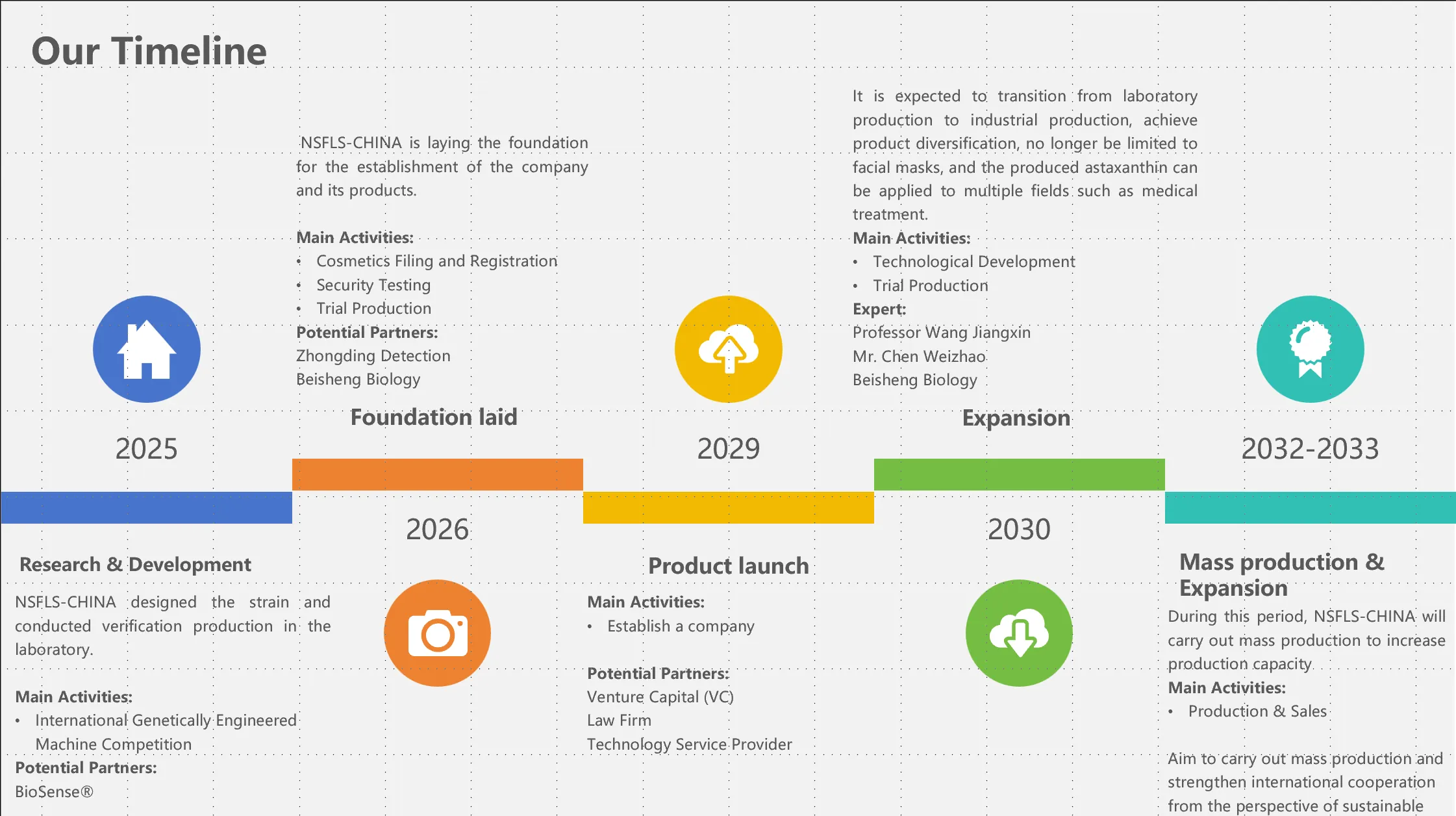

Figure 3. This is a summary chart of the company's development timeline.

Figure 3. This is a summary chart of the company's development timeline.

At this stage, NSFLS-CHINA designed the strain and conducted verification production in the laboratory.

International Genetically Engineered Machine Competition

Our Product Research & Development journey began with the iGEM (International Genetically Engineered Machine) project. Through this project, NSFLS-CHINA successfully synthesized the expected product, astaxanthin, and applied the finished product to facial masks in a laboratory environment

Potential Partners

BioSense® is a synthetic biology company specializing in biological design and manufacturing. They provide laboratory space and equipment to assist NSFLS-CHINA with laboratory-stage Product Research & Development. Additionally, they offer valuable advice and guidance throughout the process.

Currently, NSFLS-CHINA is laying the foundation for the establishment of the company and its products.

Cosmetics Filing and Registration

Cosmetic filing and registration are statutory access documents issued by drug regulatory authorities, allowing cosmetics to be produced and sold within China. To obtain this permit, systematic evaluations of product safety, efficacy claims, and production compliance must be conducted. In addition, if NSFLS-CHINA wishes to independently produce and sell products, it must also obtain a cosmetic production license and pass the Cosmetic Good Manufacturing Practice (GMPC) certification.

Security Testing

The Cosmetic Safety Evaluation Report is a legal technical document for product filing/registration, used to prove the safety of cosmetics to human health. To obtain market approval, toxicological tests, stability tests, and human safety verification must be conducted on the product in accordance with the Cosmetic Safety Technical Specification. In addition, for special efficacy claims (such as sun protection, freckle removal), NSFLS-CHINA also needs to submit a human efficacy evaluation report and safety certification documents for relevant raw materials.

Trial Production

The trial production batch record of cosmetics is the core process validation document for filing/registration, proving that the product can be stably scaled up for production. To obtain marketing authorization, NSFLS-CHINA must complete at least 3 consecutive batches of trial production in a Good Manufacturing Practice (GMP)-certified workshop, and conduct full-item quality inspections and stability studies on each batch of products. In addition, to independently carry out commercial production, NSFLS-CHINA also needs to obtain a cosmetics production license and pass the on-site dynamic production inspection by the drug regulatory department.

Potential Partners

Zhongding Detection: Zhongding Testing Technology Co., Ltd. (CTT) is a professional third-party technical service institution specializing in the fields of consumer goods, cosmetics, agricultural products, etc., and has qualifications such as a cosmetics registration and filing inspection and testing institution and a special food verification and evaluation technical institution of the State Administration for Market Regulation. They can provide NSFLS-CHINA with professional cosmetics testing, registration and filing, as well as cosmetics security compliance testing services, assisting NSFLS-CHINA in the compliant production of its products.

Beisheng Biology:Bioosen® has established an industrial layout for early cases of biotechnology R&D infrastructure and fermentation beverage solutions in the era of synthetic biology, and has rich experience in collaborating with industrial enterprises to carry out product trial production; therefore, collaborating with them can generate important insights, practical suggestions, and guidance.

Establish a company

Establishing a company is crucial for the successful entry of the astaxanthin cosmetics developed by NSFLS-CHINA into the market. If NSFLS-CHINA wishes to register as a legal entity, it must clearly define its business operations and submit a detailed list of shareowners to the relevant regulatory authorities.

The company's organizational structure

A clear corporate structure can provide fundamental support for a company's long-term growth by promoting specialization, enabling continuous improvement, and building adaptability. The strong scalability it confers ensures that the company can smoothly integrate new roles and business modules during the expansion phase. This stability forms the cornerstone of sustainable development, laying a solid and resilient implementation foundation for the efficient achievement of long-term business objectives.

Board of Directors

The Board of Directors is a group of individuals elected to represent the interests of NSFLS-CHINA shareowners,including Chairman and Shareowner Representative.

Chief Executive Officer (CEO)

The Chief Executive Officer (CEO) is an executive of NSFLS-CHINA, responsible for major decision-making, overall operations, and communication with the board of directors and stakeholders.

Product Research & Development Department

NSFLS-CHINA Product Research & Development Department is responsible for innovating and improving NSFLS-CHINA's products through research, design, and testing to meet customer needs and enhance market competitiveness.

Finance Department

The finance department manages financial activities, including budgeting, forecasting, accounting, and financial reporting, to ensure effective quota and financial health.

Human Resources

The Human Resources department is responsible for managing employee recruitment, training, development, benefits, and compliance with labor laws, understanding the workforce and culture of the company's employees, making good use of talent, and assigning each employee to a suitable position to improve the company's productivity and efficiency.

Operations Department

The Product Production Department

The Product Production Department is responsible for efficiently producing and packaging astaxanthin cosmetics while ensuring that the quality meets the standards.

Sales Department

The Sales Department is responsible for generating revenue, building customer relationships, and achieving sales targets through the promotion and sale of astaxanthin cosmetics.

Venture Capital (VC)

Venture capital firms provide equity financing to startups with high growth potential and may also offer support in the form of industry resources and management experience (such as helping to establish connections with customers and optimize business models).

Law Firm

Law firms can assist in completing the company registration process (such as equity structure design and company charter formulation), handle intellectual property protection matters such as trademark registration and patent application, as well as legal affairs such as contract review and labor compliance. Especially for companies involved in equity financing, joint ventures, and cooperation, lawyers can provide professional legal framework design to avoid subsequent disputes.

Technology Service Provider

Technology service providers, such as IT companies (building official websites and management systems), design companies (brand logo and VI design), etc., assist our company in completing basic digital construction and shaping brand perception.

It is expected to transition from laboratory production to industrial production, achieve product diversification, no longer be limited to facial masks, and the produced astaxanthin can be applied to multiple fields such as medical treatment.

Technological Development

NSFLS-CHINA will focus on the R&D of simplified solutions for large-scale product production, with technological breakthrough dimensions including the upgrade of precise gene design, the improvement of model organism production efficiency, and the innovation of production hardware architecture.

Expert

Exchanges with industry experts such as Professor Wang Jiangxin and Mr. Chen Weizhao can provide NSFLS-CHINA with valuable professional advice and methods, thereby improving the accuracy and effectiveness of the transformation.

Beisheng Biology

BioSun® has extensive experience in the transition from laboratory to industrial facilities. Centered around strain design and manufacturing, it has established a new generation of high-throughput molecular and strain manufacturing platforms, with the capabilities to produce hundreds of millions of DNA molecules, purify several kilograms of proteins, and generate millions of strains, thereby promoting the industrialization of biotechnology R&D. Collaborating with BioSun® can provide valuable insights, practical advice, and professional guidance during the transformation process, facilitating the industrialization of technological achievements and driving the upgrading of the fermentation industry.

During this period, NSFLS-CHINA will carry out mass production to increase production capacity.

Production

The mass production plan will be implemented according to market demand. This production will be advanced through cooperation between the factory and NSFLS-CHINA.

Sales

NSFLS-CHINA will open online stores on different e-commerce platforms such as Tmall, JD.com, Amazon, eBay, etc., and cooperate with various distributors across the country.

To maintain a long-term competitive advantage, we aim to carry out mass production and strengthen international cooperation from the perspective of sustainable development

Product Development

NSFLS-CHINA will conduct extensive research and development in the laboratory to create innovative products that meet unmet needs, such as skincare and makeup alternatives inspired by Chinese drama masks and astaxanthin energy bars. In addition, the company will conduct rigorous testing before launching product prototypes to ensure their quality, safety, and effectiveness.

Expand international markets

NSFLS-CHINA will precisely target the market and prioritize regions with friendly policies and matching demand. The company will identify pain points and growth opportunities in potential non-Chinese markets while studying local regulations, competitive product landscapes, and consumer preferences. This approach will enable the company to effectively expand into new markets and enhance its global influence.

Moreover, the regulatory rules and standard requirements for cosmetics vary from country to country. Therefore, in order to sell our products in the international market, it is necessary to register and file cosmetics in accordance with local regulations.

We use the astaxanthin produced by our cell factory as the primary product. By integrating the creative feedback from Shenzhen citizens and drama actors, we now introduce three secondary products to better cater to different consumer groups.

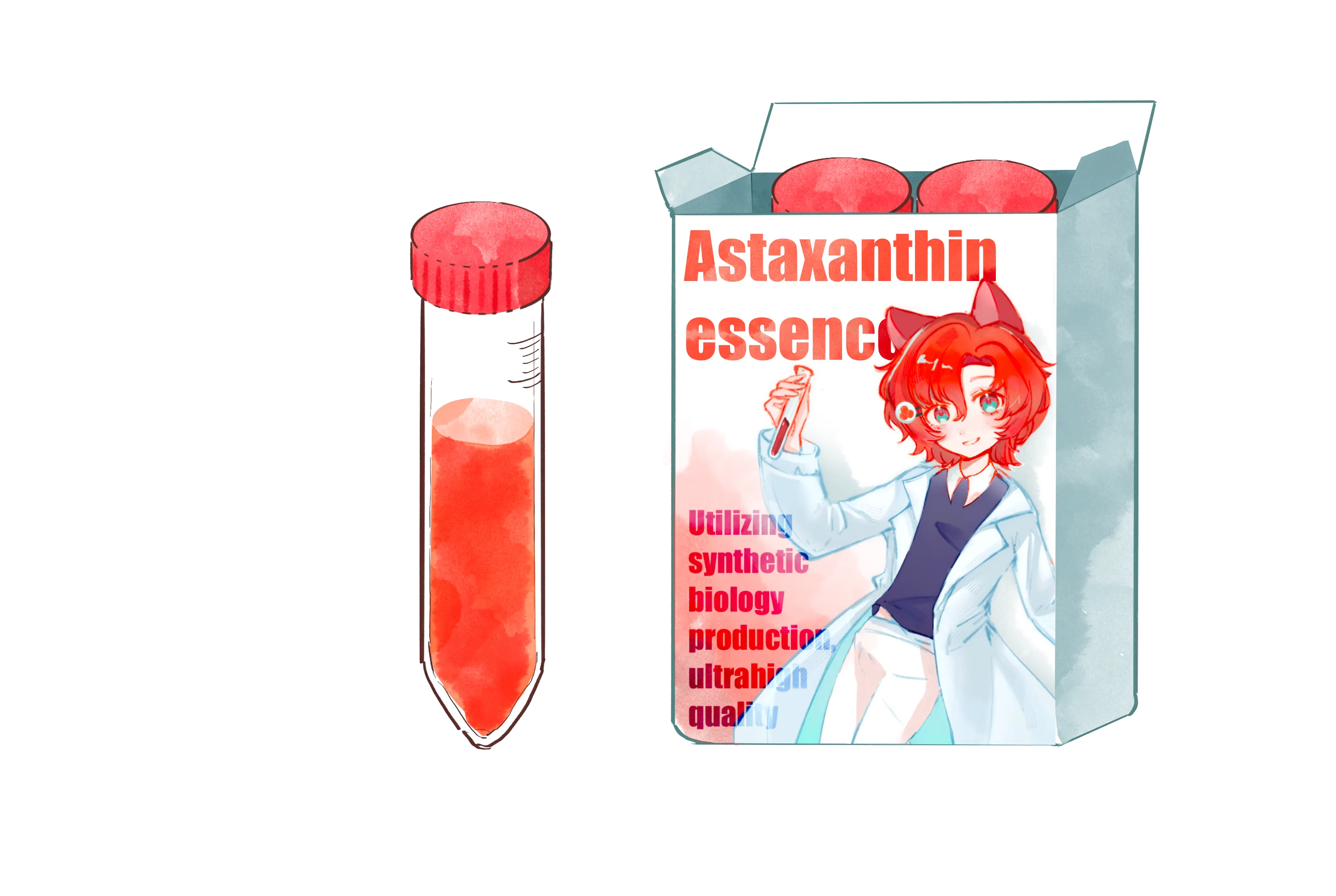

The first product is astaxanthin essence. The packaging design is inspired by laboratory centrifuge tubes, echoing the background of synthetic biology. At the same time, the team created an exclusive cartoon character to enhance the brand's appeal and attract young consumers.

Figure 4. Example picture of Astaxanthin Essence product

Figure 4. Example picture of Astaxanthin Essence product

The second product is an enhanced version of the red makeup line, targeting the theater actress market. The packaging adopts an ink-wash style to incorporate traditional Chinese elements, while the eye makeup part incorporates the style of traditional Chinese opera, balancing artistry and cultural inheritance.

Figure 5. Example images of the red drama improved makeup products

Figure 5. Example images of the red drama improved makeup products

The third product is the astaxanthin facial mask. It features a simple and elegant design, and is mainly targeted at consumers who have demands for anti-aging and skincare. It conveys the product philosophy of professionalism and practicality.

Figure 6. Astaxanthin mask sample picture

Figure 6. Astaxanthin mask sample picture

Pricing strategy: stepwise pricing is adopted, with the purchase volume ≥10 tons/year and the unit price is 800 USD /kg; 5-10 tons/year, the unit price is 850 USD /kg; <5 tons/year, the unit price is $900 /kg;

Customer cooperation: sign a three-year long-term agreement with the head customer, guarantee the minimum purchase quantity of 5 tons/year, provide 5% price discount; For small and medium-sized customers to provide "first trial order after batch" service, trial order quantity ≥100kg, unit price 950 USD /kg;

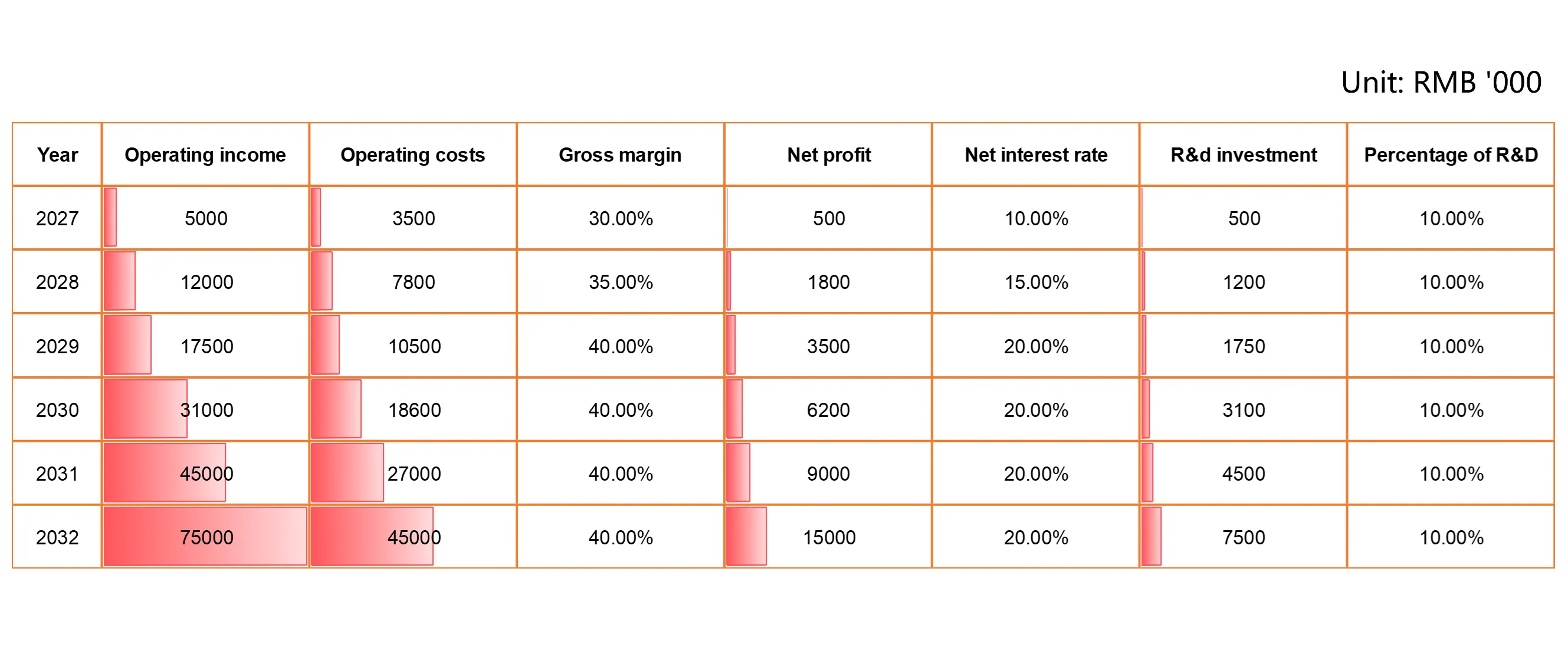

Revenue forecast: B2B revenue of RMB15 million (30%) in 2027, RMB80 million (45%) in 2029 and RMB300 million (40%) in 2032.

Product pricing: Mask 128 yuan/box (5 tablets), essence 298 yuan/bottle (30ml), lotion 268 yuan/bottle (50ml), 15-20% lower than similar products;

Online: Tmall, Jingdong flagship store (50%), Xiaohongshu, Douyin live (30%), subscription system (20%);

Offline: Watsons, Sephrand (60%), brand counters (40%);

Revenue forecast: B2C revenue of 35 million yuan (70%) in 2027, 95 million yuan (55%) in 2029 and 350 million yuan (47%) in 2032.

Cooperation mode: Customize and develop astastain products for well-known brands (such as L 'Oreal and Shiseido), and charge development fee (500,000 to 1 million yuan/style) + OEM fee (10-15% increase in unit price);

Case: In 2028, we plan to cooperate with an international brand to develop astastain makeup primer. The development cost is 800,000 yuan, the foundry volume is 1 million bottles, and the foundry income is 20 million yuan.

Revenue forecast: 5 million yuan in 2028, 15 million yuan in 2030 (5%), and 10 million yuan in 2032 (1.3%) from cooperative development.

Authorization mode: to authorize strains and processes from regional manufacturers, charge preliminary authorization fee (RMB 5 million/company) + sales commission (3%), and the authorization period is 5 years;

Target customers: small and medium-sized cosmetics manufacturers in Southeast Asia and South America (lack of technical ability), 5 of which are planned to be authorized in 2030 and 10 in 2032;

Revenue forecast: 25 million yuan (8%) of technology licensing revenue in 2030 and 50 million yuan (6.7%) in 2032.

Table 2. This is the financial forecast for our company from 2027 to 2032.

Table 2. This is the financial forecast for our company from 2027 to 2032.

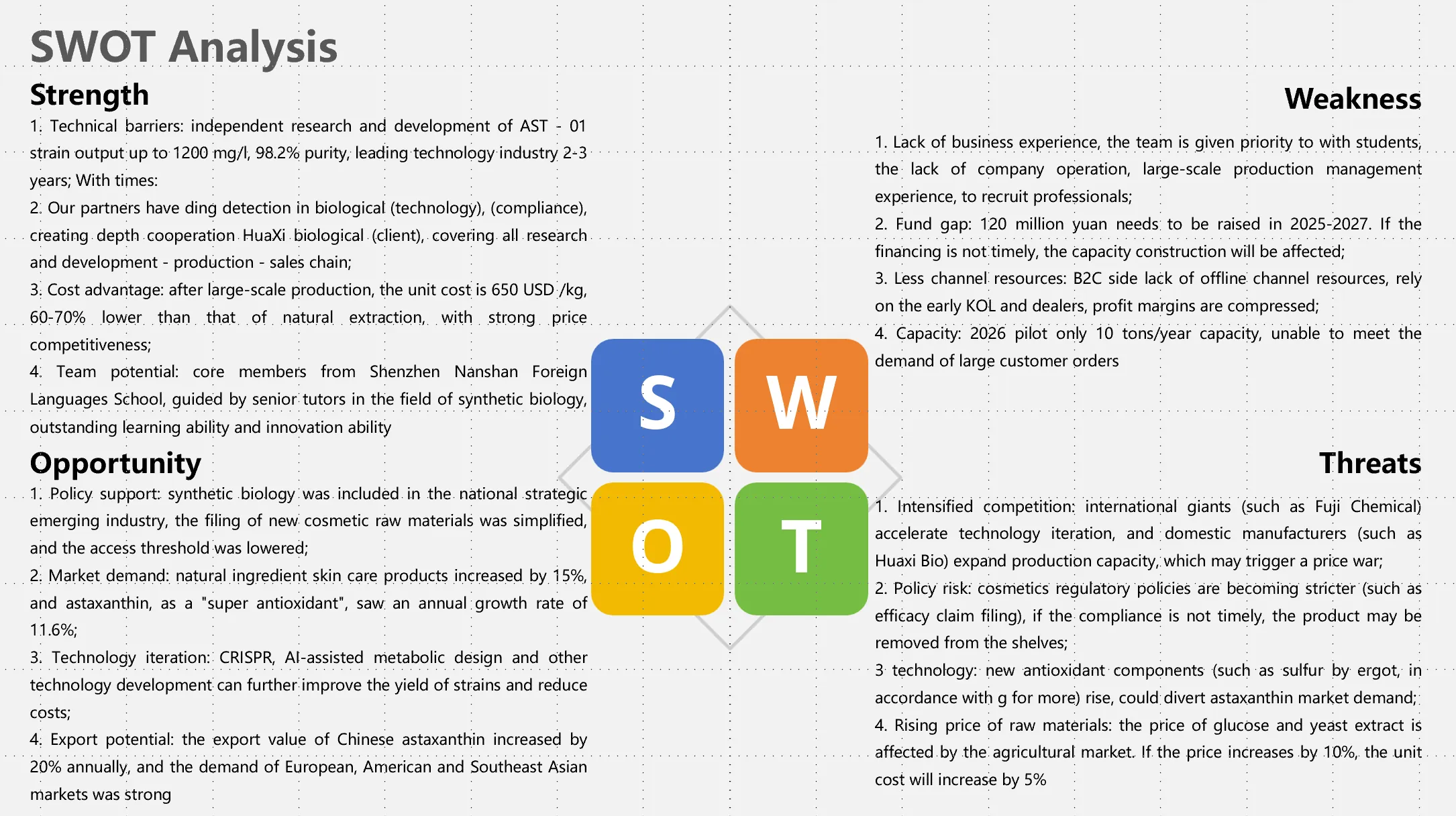

This part will systematically analyze the core resources, core capabilities, key capability gaps and coping strategies of NSFLS-CHINA project, and comprehensively evaluate the internal and external conditions of the project based on SWOT analysis.

Figure7. The SWOT analysis summary chart of the company.

Figure7. The SWOT analysis summary chart of the company.

At present, our project has built a key resource system to support its initial development:

Patent technology resources: The project has submitted Chinese invention patent application (Application No. : CN202511043781.7) and PCT international patent application (Application No. : PCT/CN2025/124139) for high-performance β-carotene hydroxylase mutant. This patent family constitutes the core technical barrier and global intellectual property assets of the project.

Research and development team and human resources: the core team by enthusiastic about synthetic biology and the preliminary scientific research practice ability of students, and in shenzhen, under the guidance of the senior adviser at the university to carry out the research and development work, to ensure the validity of the research direction and professional.

Partners and hardware resources, has established cooperative relations with deep university, for its advanced laboratory platform and equipment support. At the same time, with The Times living creatures (Biosysen) experience in industrialization of companies such as connection is established, which laid a foundation for subsequent scale-up.

Data and knowledge resources: The protein structure simulation and molecular docking were completed through AlphaFold, CB-Dock2 and other tools, and the preliminary verification data of mutant improving astaxanthin yield (such as CYS191ALA mutant increasing yield by 1.28 times) were obtained through experiments, forming a valuable knowledge base of proprietary technology.

Based on existing resources, the project has the following core capabilities:

Synthetic biology research and development and strain construction: The team has successfully completed the transformation and verification from gene sequence design, plasmid construction (pETDuet-1 vector, 7 key genes) to engineering strain (E. coli BL21(DE3)), and mastered the whole process of strain development at laboratory level.

Bioinformatics and rational design capability, able to skillfully use of bioinformatics tools such as protein structure prediction, molecular docking, guide the key enzyme of directed evolution, embodies the efficient research and development of "rational design" mode.

Lab-level process development capability: A complete set of laboratory process flow from small-scale fermentation (IPTG induction), cell collection, vacuum freeze-drying to solvent extraction (methanol: isopropyl alcohol) and HPLC quantitative analysis has been established and optimized.

We are keenly aware that there are still key capacity gaps in the process of industrialization of the project, and have formulated clear coping strategies:

Large-scale production and process scale-up capabilities:

Marketing, sales and business development capabilities:

Financial and comprehensive management ability of the Company:

NSFLS-CHINA project has a solid foundation of resources and capabilities in technology research and development, and has initially built an external support network through cooperation with universities and enterprises. SWOT analysis further clarifies the strengths, weaknesses, opportunities and threats of the project, which provides a basis for strategy formulation. For the key capabilities and resource gaps required for industrialization, the team has planned clear and pragmatic solutions, and systematically promoted the commercialization process of the project through phased talent introduction, financing plan and resource construction. This reflects the team's clear understanding of itself and careful planning for the sustainable development of the project.

Peer competition

Competitors may sell biosynthetic astaxanthin at lower prices, and some existing enterprises have already launched low-cost synthetic astaxanthin, which in turn affects our market share and profitability.

Response Measures Strengthen the endorsement of bioactivity data for natural configuration astaxanthin, conduct market surveys to identify major competitors, and use this information to optimize our competitive positioning. Enhance product differentiation by focusing on unique features and value-added services.

Market demand

Fluctuations in the demand for astaxanthin in the cosmetics industry may lead to poor sales and poor return on investment.

Response Measures Prioritize entry into densely populated areas of developed cities and the incremental antioxidant market in South East Asia.

Budget Overrun

Production costs may exceed expectations, leading to a shortage of funds.

Response Measures Targeted attraction of industrial investment funds in the field of biomanufacturing; application for special project policy subsidies for synthetic biology

Poor Financial Management

Improper control of procurement costs for key materials such as enzyme immobilization carriers.

Response Develop a practical and detailed budget plan through regular reviews. Monitor expenditures and adjust the plan as needed to avoid overspending.

Key Personal Flow

The loss of the Directed Evolution Algorithm Team will impede the improvement of enzyme catalytic efficiency.

Response Empower core members with the right to share the dividends of strain patents, provide competitive compensation and a dynamic working environment to retain talent. Establish clear archiving and cloud backup mechanisms to ensure information retention.

Policy Change

The adjustment of the archiving rules for new cosmetic raw materials has increased compliance costs.

Response Establish a cross-functional compliance team; allocate a budget to revalidate the retained strains to adapt to changes.

Vision

To become the world's leading provider of green cosmetic ingredients and solutions based on synthetic biotechnology.

Mission

To provide efficient, safe and affordable natural astaxanthin products to the global market through sustainable innovative technologies, improve consumer skin health and promote green development in the beauty industry.

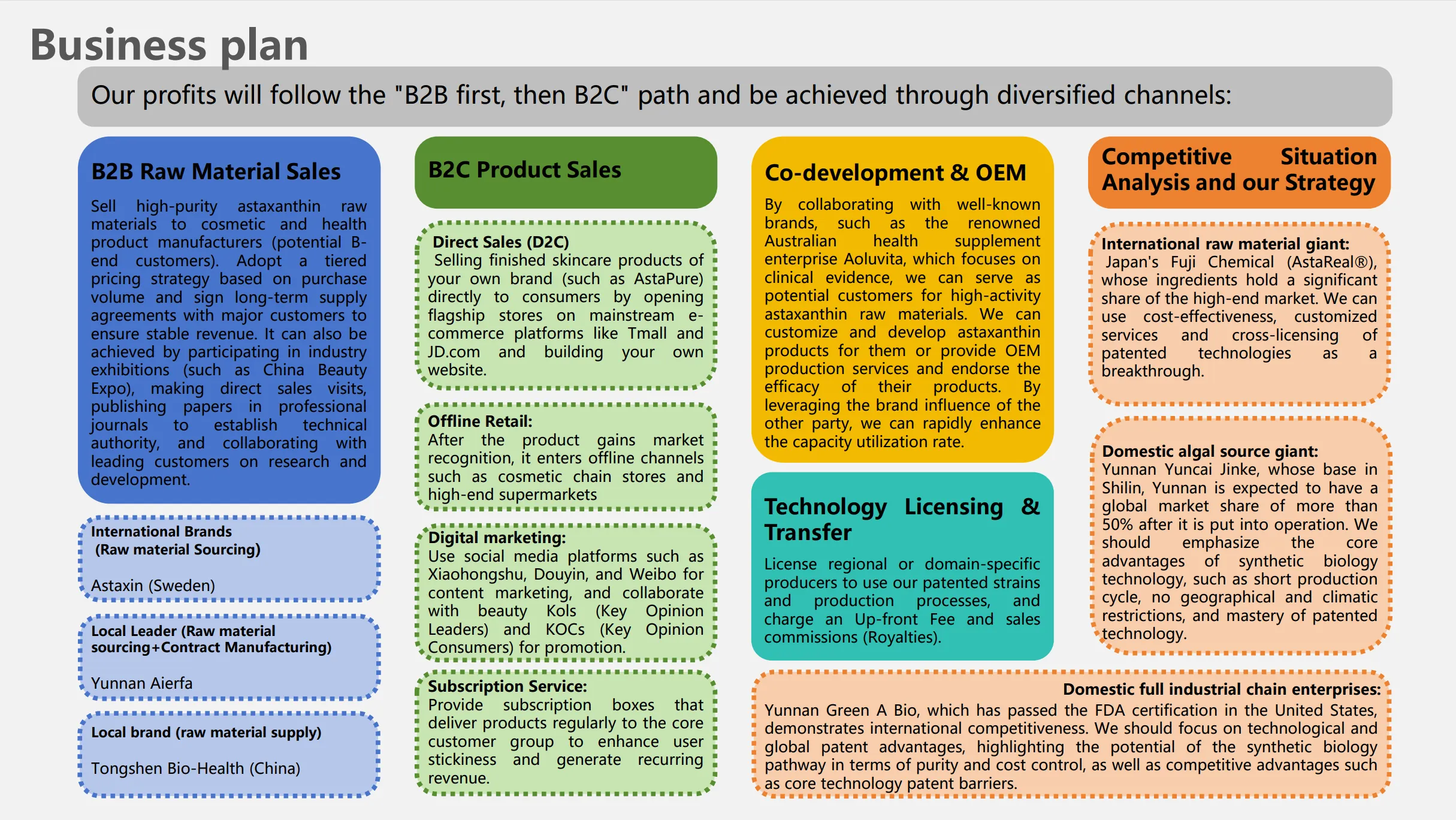

Our profits will follow the "B2B first, then B2C" path and be achieved through diversified channels:

We have carefully considered our growth plan. Our business model clearly outlines our development plan, including the resources involved and the key activities. We have also based our development plan on this.

Figure 8 . This is the summary diagram of the company's business plan.

Figure 8 . This is the summary diagram of the company's business plan.

B2B Raw Material Sales

Sell high-purity astaxanthin raw materials to cosmetics and health supplement enterprises through tiered pricing and long-term agreements. Expand customer base through industry exhibitions, technical cooperation and direct sales, and establish supply chain relationships with both domestic and international brands.

B2C Product Sales

Carry out D2C sales through e-commerce platforms and self-built websites, and expand the market by leveraging offline channels. Utilize social media and KOLs for digital marketing, and enhance user stickiness and repeat purchases through subscription services.

Co-development & OEM

Collaborate with well-known brands, offering customized product development or OEM production services. Leverage the influence of the partner brand to increase production efficiency.

Technology Licensing & Transfer

License regional or domain-specific producers to use our patented strains and production processes, and charge an Up-front Fee and sales commissions (Royalties).

Competitive Situation Analysis and our Strategy

In the face of both international and domestic competitors, we adopt cost advantages, customized services, and technological barriers in synthetic biology as our differentiation strategies for competition.

Regarding the exit strategy, NSFLS-CHINA takes Initial Public Offering (IPO) as one of its core exit strategies. We plan to achieve the transformation from a private enterprise to a Listed Company by offering shares to the public. Although this path is highly challenging and has strict requirements for product market influence and branding impression, it also contains great potential for value release. We will promote our business through keynote speeches, technology demonstrations, etc., and enhance product market awareness through diversified channels such as industry summits and media cooperation. At the same time, we will carry out online and offline brand activities to strengthen end users' perception of product value. Through Initial Public Offering (IPO), we can obtain substantial profits upon exit, thereby enhancing the publicity, social Reputation, and branding impression of the company's products, injecting capital impetus into the company's subsequent development, laying a solid foundation for long-term strategic layout, and achieving the organic unity of short-term interests and long-term development.

We can also choose a widely used exit route - merger and acquisition (M&A) exit, which involves having the company acquired by another enterprise with more experience in business operations and a larger scale. This approach can maximize the retention of our autonomy, allowing us to still have a say in product development and pricing strategies: we can either choose to continue in-depth involvement, controlling the price system and the direction of product iteration; or completely divest the business to achieve a full exit. If our core product is successfully approved, we can seek to merge with a well-known large cosmetics group. By leveraging its established distribution network and brand influence, we can not only continue to drive market penetration of our existing product lines, but also rely on the other party's resource advantages to expand the R&D and output of new product categories, creating more room for the continuous release of brand value while achieving a smooth transition. This flexible exit model takes into account the option of controlling the business and also injects new possibilities into enterprise development.

If none of the above strategies prove effective, we can choose equity stake transfer as the final exit strategy. We can relatively flexibly transfer our equity stake in the enterprise to other investors and select a suitable transferee based on the actual situation of the enterprise. However, this option will only be considered when neither of the above two strategies works.

Behind the NSFLS-CHINA team is a group of outstanding students from Shenzhen Nanshan Foreign Languages School, a well-known institution in Shenzhen full of passion and vitality. Each member has their own unique interests and personality, and they excel in a wide range of fields such as natural sciences, social sciences, science and engineering, and liberal arts, ensuring that different knowledge perspectives and ideas can achieve cooperation through collision, paving the way for the harmonious development of the NSFLS-CHINA team. Despite the challenges, the team atmosphere is very friendly and collaborative. In addition, the experimental skills, social practice experience, and excellent research results gained in the vibrant campus enable us to fully engage in the continuous development of the project. With a relatively in-depth understanding of the appearance anxiety and aging issues currently plaguing society, NSFLS-CHINA is firmly moving towards its ultimate goal - deciphering the code of youth, launching more environmentally friendly antioxidant skincare products, enabling the people we love to have better looks, and alleviating social appearance anxiety.

With the help of experienced mentors, the potential of team members has been further tapped, enabling us to gain a deeper understanding of relevant topics and thus turn the team's goals and dreams into reality. Moreover, our achievements are largely attributed to the close connection with Shenzhen University, which provides experimental equipment, allowing us to conduct in-depth research and thrive in well-equipped laboratories, validating our constructive ideas.

We are committed to becoming a pioneer in the field of anti-aging skincare, continuously driving industry innovation through cutting-edge technology. Our research aims to make anti-aging skincare more healthy and sustainable, benefiting humanity and the environment, and ensuring the provision of anti-aging skincare products and cosmetics that combine health benefits with safety guarantees for global consumers. In our in-depth research in the anti-aging field, we always adhere to "health" and "sustainability" as core principles. From the screening of bioactive ingredients to the optimization of formulation systems, every step of exploration is dedicated to reducing the burden on the skin and minimizing the impact of the production process on the ecosystem, striving to contribute to the sustainable development of the planet while maintaining the youthful state of human skin.

This unwavering commitment to innovation will ultimately enable anti-aging skincare products nourished by technology to enter the lives of more people, ensuring that beauty and responsibility always go hand in hand.

Given the challenges faced by anti-aging products and the limitations of existing astaxanthin production methods, NSDFLS-CHINA is committed to developing safe, environmentally friendly, and cost-effective products using synthetic biology. Based on our analysis, our products will have the following impacts on people's health, society, and even the environment.

Traditional astaxanthin products often have two major health risks: natural extraction is prone to introducing impurities due to raw material contamination (such as heavy metals in sea areas, pesticide residues in algal bodies, etc.), while chemical synthesis may leave behind toxic catalysts (such as heavy metal compounds), and long-term use may lead to problems such as skin sensitivity and metabolic burden. In contrast, NSDFLS-CHINA's astaxanthin achieves "clean synthesis" through synthetic biology technology in an engineered E.coli system - the fermentation process uses food-grade culture medium, has no exogenous pollutants, and can directionally synthesize highly active left-handed (3S-3'S) configuration astaxanthin (which has stronger compatibility with human skin). Verified by a third-party testing agency, the product purity reaches 98.2%, with no risks of heavy metals, pesticide residues, etc.

In terms of health benefits, this product not only meets anti-aging skincare needs (such as reducing fine lines and improving dullness by scavenging free radicals in the skin), but its stable molecular structure can also be better absorbed by the human body, helping to enhance the body's antioxidant capacity (such as reducing skin damage from ultraviolet rays and lowering oxidative stress after exercise), providing an "internal and external synergy" health solution for different groups of people (such as night owls, outdoor workers, and middle-aged and elderly people).

From an industrial perspective, this product has broken the foreign monopoly on high-purity astaxanthin production technology (for example, the traditional high-end astaxanthin market has long been dominated by Japanese and US enterprises, relying on natural algal strain cultivation technology). NSDFLS-CHINA has built an independently controllable fermentation production system through synthetic biotechnology, which not only lowers the production threshold of astaxanthin (compared with traditional natural extraction, equipment investment costs are reduced by 40%), but also drives the development of upstream and downstream industries - upstream, it can stimulate the demand for supporting industries such as food-grade culture media and bioreactors, and downstream, it provides cost-effective raw materials for industries such as cosmetics and health products, helping domestic beauty and health industries transform from "raw material import dependence" to "self-developed technology empowerment" and enhancing the competitiveness of local industries.

From a people's livelihood perspective, this product combines both "universality" and "accessibility": on the one hand, in response to anti-aging skincare needs, its stable characteristics can be adapted to various skincare product formulations such as masks, serums, and lotions. After large-scale production in cooperation with manufacturers in the future, more affordable and high-quality anti-aging products can be launched, allowing ordinary consumers to avoid the cost of high-priced imported products; on the other hand, in remote areas or areas with weak medical resources, as an antioxidant supplement that is easy to store and transport, this product can help improve the health security conditions of local residents and provide grassroots support for the construction of a Healthy China.

Traditional astaxanthin production models impose a heavy burden on the environment: natural extraction relies on large-scale cultivation of Haematococcus pluvialis, which requires a vast amount of arable land or sea area, and the cultivation process requires precise control of water temperature and light, with extremely high energy consumption (producing 1 kilogram of natural astaxanthin consumes 3,200 kilowatt-hours of electricity); chemical synthesis generates a large amount of acidic wastewater and organic waste gas.

The synthetic biology production model of NSDFLS-CHINA has achieved "triple environmental protection breakthroughs": First, it has low resource consumption. The fermentation process mainly uses renewable raw materials such as glucose and amino acids, without the need to occupy arable land or sea areas. Through metabolic optimization of engineered bacteria, the raw material conversion rate reaches 82% (the raw material conversion rate of traditional natural extraction is only 30%), significantly reducing resource waste. Second, it has low pollution emissions. Fermentation wastewater can be recycled after simple treatment (such as for irrigation and cleaning), without generating toxic and harmful waste. According to environmental assessments, the carbon emission per unit of output is only 1/5 of that of chemical synthesis and 1/3 of that of natural extraction. Third, it has strong risk resistance. It does not rely on the natural environment (for example, natural algal strains are vulnerable to climate change and may experience reduced yields). Indoor fermentation enables stable production, avoiding indirect damage to the ecosystem caused by fluctuations in raw material supply (such as overfishing of shrimp and crabs to obtain shrimp shells and overdevelopment of sea areas for cultivating Haematococcus pluvialis), setting a green benchmark of "low consumption, emission reduction, and sustainability" for the biomanufacturing industry.

[1] Tominaga K, Hongo N, Fujishita M, Takahashi Y, Adachi Y. Protective effects of astaxanthin on skin deterioration. J Clin Biochem Nutr. 2017 Jul;61(1):33-39. doi: 10.3164/jcbn.17-35. Epub 2017 Jun 20. PMID: 28751807; PMCID: PMC5525019.

[2] Tominaga K, Hongo N, Karato M, Yamashita E. Cosmetic benefits of astaxanthin on humans subjects. Acta Biochim Pol. 2012;59(1):43-7. Epub 2012 Mar 17. PMID: 22428137.

[3] Hu Chengjie, Mao Yin, Li Guohui, Deng Yu the study on the production of glycolic acid from low-cost biomass by E.coli fermentation and its separation and purification 2024 Mar 21st

[4] Tominaga K, Hongo N, Karato M, Yamashita E. Cosmetic benefits of astaxanthin on humans subjects. Acta Biochim Pol. 2012;59(1):43-7. Epub 2012 Mar 17. PMID: 22428137.