Aiming to meet market demand for high-quality astaxanthin, our team developed a novel biosynthetic pathway for astaxanthin,based on the reference[1]. We firstly produced astaxanthin with metabolic engineering techniques in E. coli cell factories, obtained E. coli cells with astaxanthin. Then we obtained astaxanthin powder by freeze-drying. Finally we obtained astaxanthin and added appropriate amount of olive oil to get astaxanthin oil. For applications, we designed three target products including essence, face mask and opera makeup pigments.

According to the reference, we revised the extraction method of astaxanthin from E. coli cells[2].

(1) Centrifuge to collect the E. coli cells containing astaxanthin and discard the supernatant.

(2) Freeze cell pellet in liquid nitrogen.

(3) Then, the sample was dried using a vacuum freeze-drying machine. After 48 hours, a powder of bacteria containing astaxanthin was obtained.

(4) Crushed the dried cell pellet into fine powder.

(5) Exactly weigh 10 mg powder into a 2.0 mL centrifuge tube.

(6) Add 0.3mg glass beads (0.5 mm in diameter) and 1 mL of olive oil into the tube.

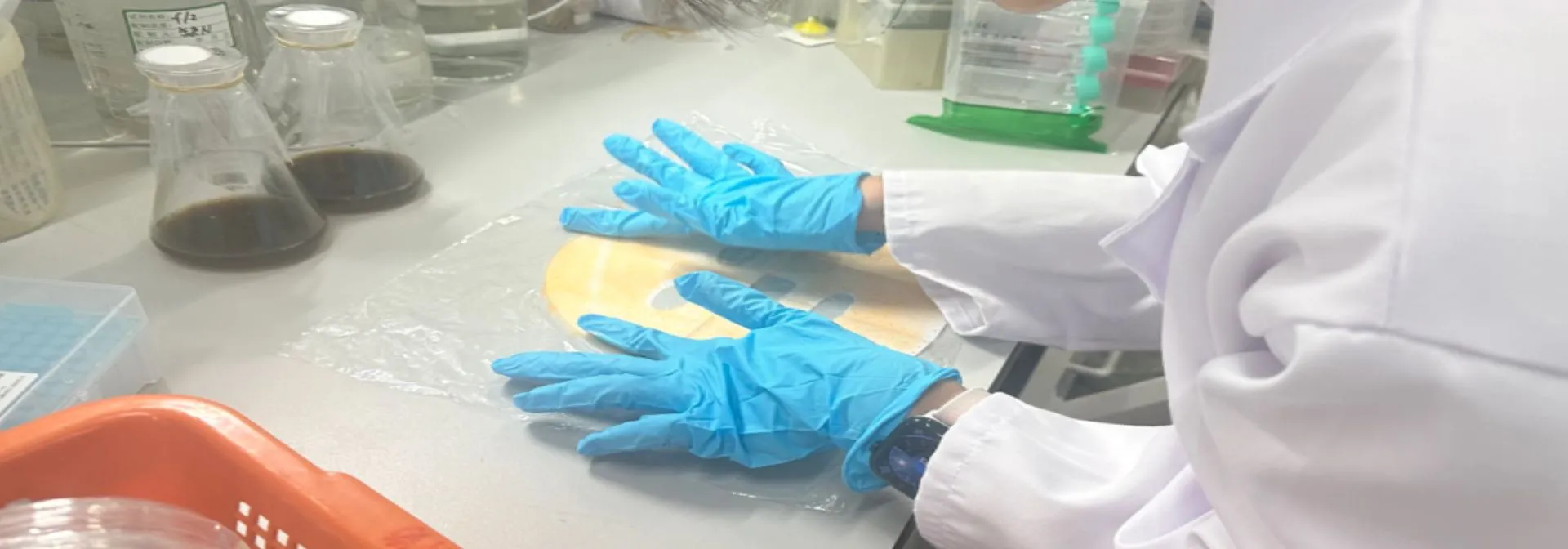

(7) Use a low-temperature grinder (setting parameters including temperature at 4°C, frequency at 60Hz, cycle at 15-second bursts with 5-second pauses) to break down the cells for 10 minutes.

(8) Centrifuge at 12,000 rpm for 2 minutes at 4°C.

(9) Suck the supernatant with a pipette to a 1.5 mL brown centrifuge tube.

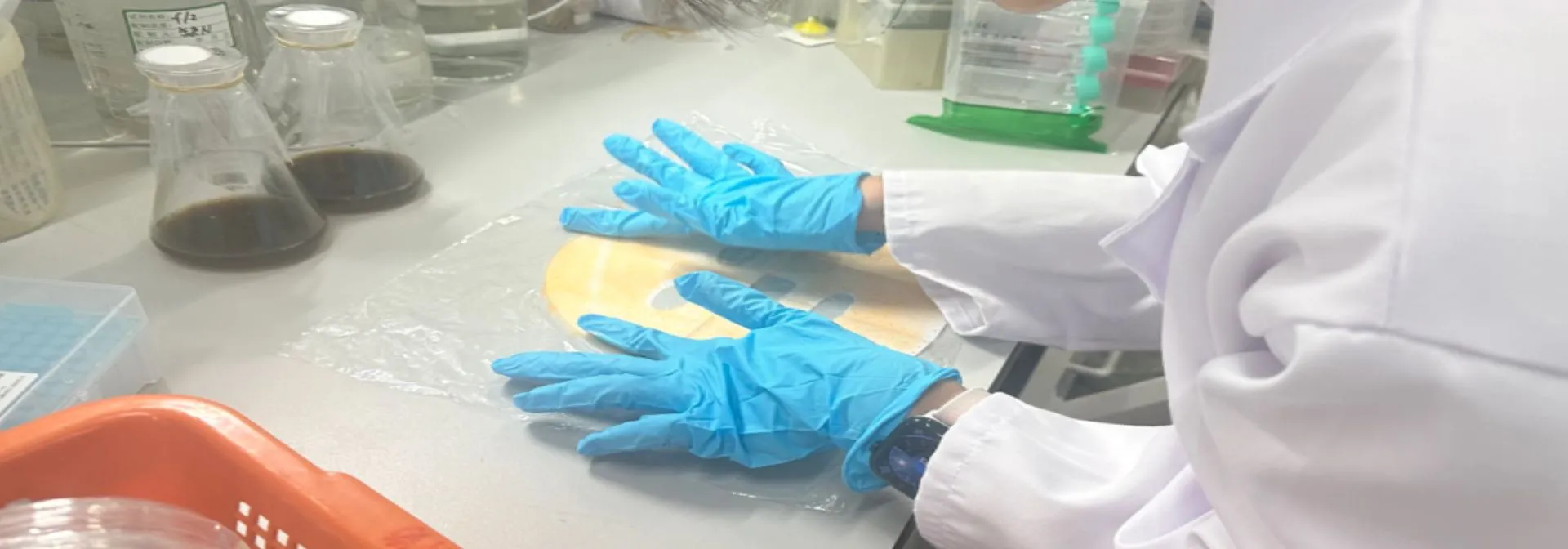

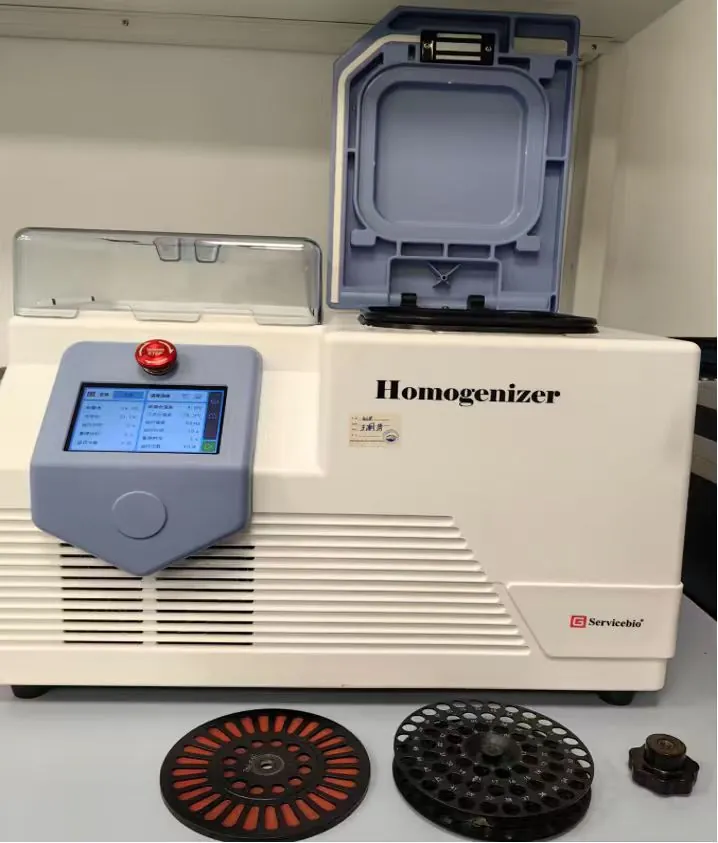

Through centrifugation and vacuum freeze-drying, we obtained E. coli cells containing astaxanthin. Subsequently, we used olive oil for oscillatory extraction, obtaining an astaxanthin-containing oil.

Figure 1. The powder after vacuum freeze-drying

Figure 1. The powder after vacuum freeze-drying

Figure 2. Homogenizer for astaxanthin extraction

Figure 2. Homogenizer for astaxanthin extraction

Figure 3. Extraction of astaxanthin-containing oils

Figure 3. Extraction of astaxanthin-containing oils

Mix water, moisturizers (glycerin, sodium hyaluronate, sorbitol, collagen), active ingredients (astaxanthin-containing oil, troxerutin), thickening agents (butylene glycol, carbomer, cellulose gum) and other raw materials (p-hydroxyacetophenone, potassium sorbate, citric acid, arginine) in the prescribed ratio. After stirring, dissolving and homogenization, a uniform essence is formed.

Follow the above steps to prepare essence for soak face mask clothes.

Cut PET plastic, silk and non-woven fabric materials into standard shapes suitable for the face (with eye, nose and mouth openings).

Place the cut film cloth into the facial mask bag (an aluminum-plastic composite bag). Inject a certain amount of essence (25 mL) to ensure that the film cloth is fully soaked.

Seal the bag by machine, expel the air inside the bag, and seal it tightly to prevent the essence from leaking and contamination.

Pack several facial masks for external packaging (such as paper boxes, plastic sealing). Print production date, shelf life and other information, and finally pack and ship.

Pass the astaxanthin solution extracted from olive oil through a cloth filter 2-3 times to remove impurities. Then, slowly evaporate some of the olive oil at a temperature below 40°C to increase the astaxanthin concentration.

Mix in the ratio of "astaxanthin oil: beeswax: vitamin E = 10:3:1". Beeswax can enhance the hardness of the pigment and improve its adhesion to the skin, while vitamin E can prevent the oxidation and discoloration of astaxanthin. Heat the mixture to around 60°C and stir until it is completely melted and uniform.

When the temperature of the mixture drops to 40°C, add a small amount of medical talcum powder (5-8 grams of 100 grams of the mixture), stir until there are no particles, making the pigment texture smoother and easier to apply; then pour it into a clean small porcelain dish, let it cool naturally to room temperature, and after solidification, it forms a solid pigment that can be used directly.

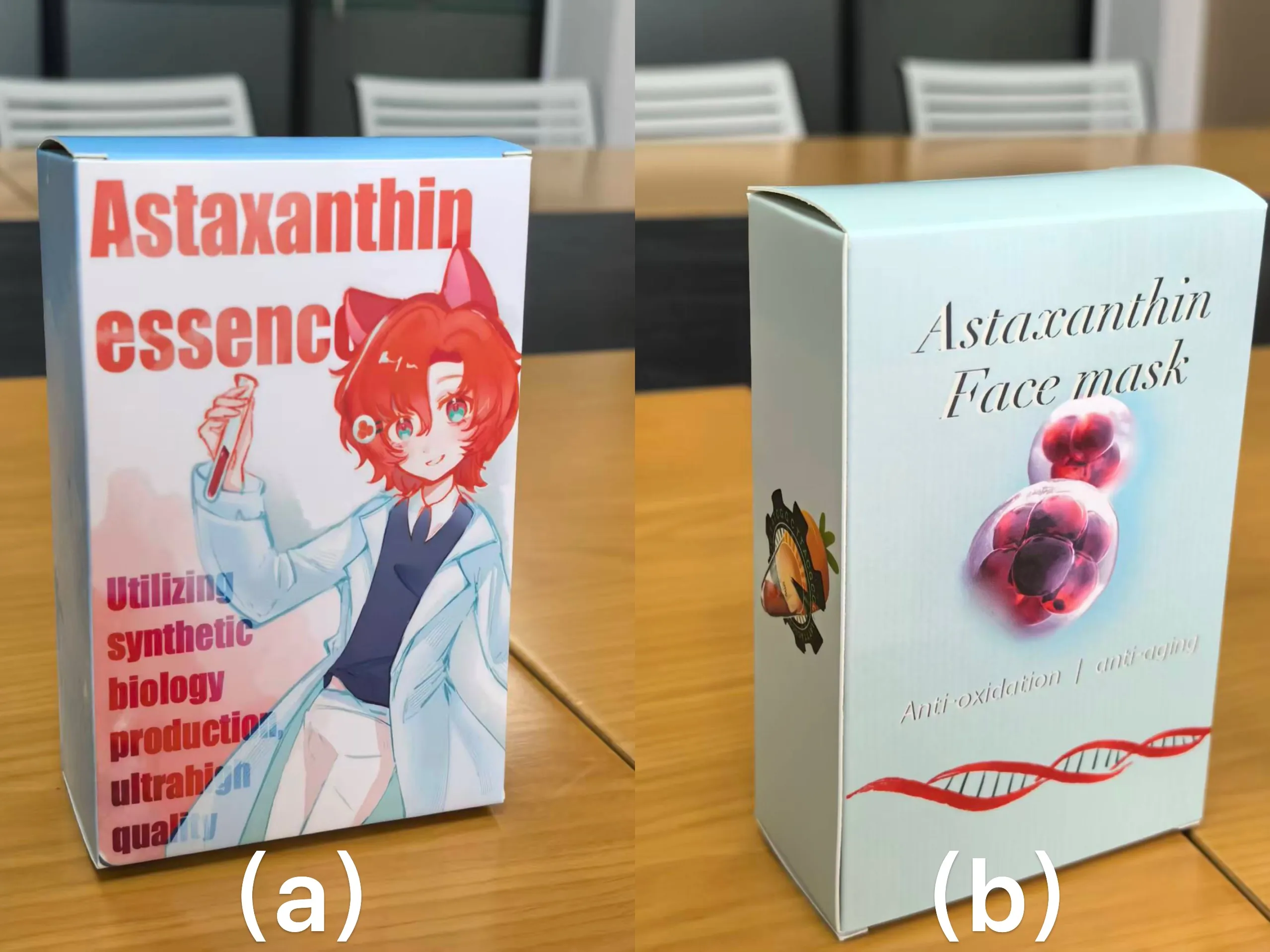

After these steps, we obtained our three target products. In order to show the basic information of our products, we also designed the outer packaging with the unique style of team for products.

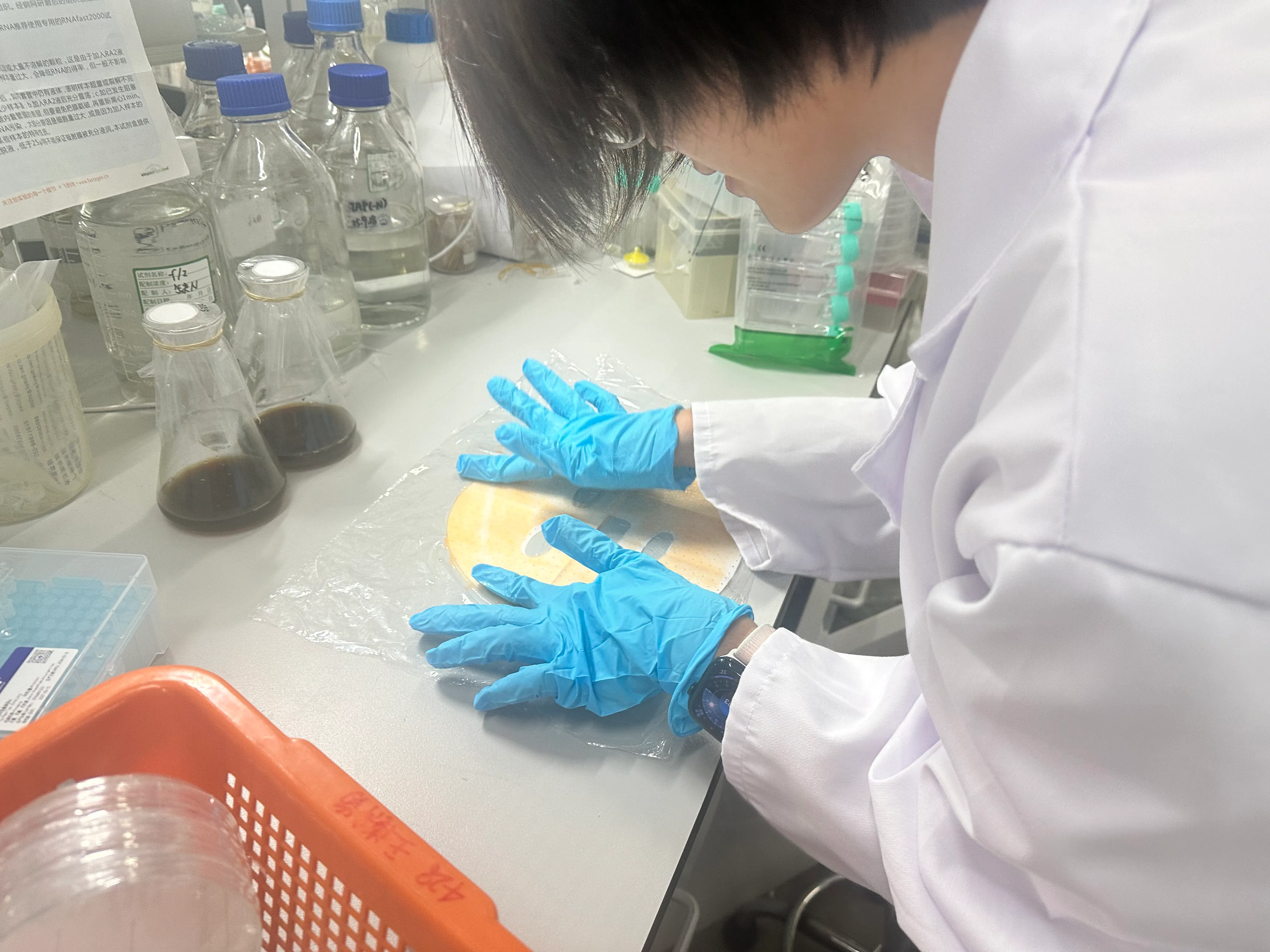

Figure 4. Production of face mask

Figure 4. Production of face mask

Figure 5. The packaging of essence(a) and face mask(b)

Figure 5. The packaging of essence(a) and face mask(b)

[1] Ma T, Zhou Y, Li X, Zhu F, Cheng Y, Liu Y, Deng Z, Liu T. Genome mining of astaxanthin biosynthetic genes from Sphingomonas sp. ATCC 55669 for heterologous overproduction in E. coli. Biotechnol J. 2016;11:228–237.

[2] Huang D, Liu W, Li A, Wang C, Hu Z. Discovery of geranylgeranyl pyrophosphate synthase (GGPPS) paralogs from Haematococcus pluvialis based on Iso-Seq analysis and their function on astaxanthin biosynthesis. Mar Drugs. 2019;17:696.